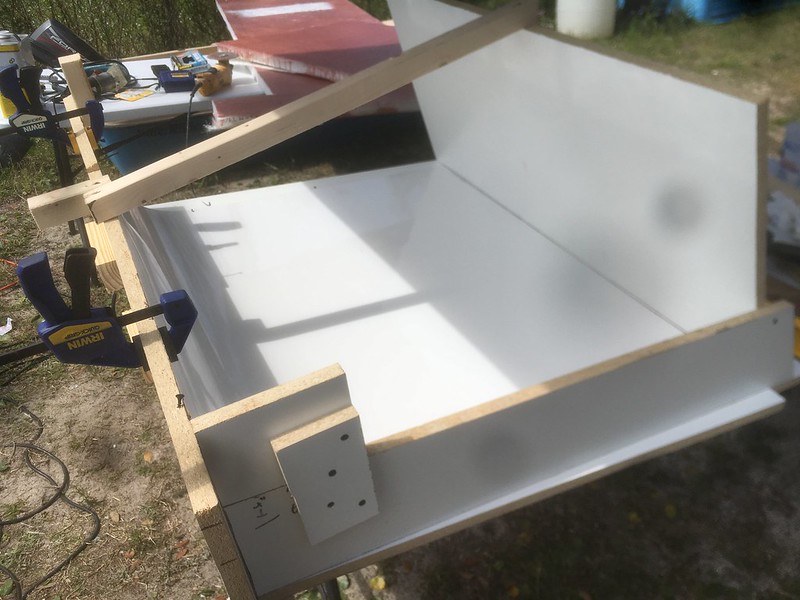

Hope to be back at the boat this weekend (weather permitting) to sand the mold and do one more coat of bondo/filler to smooth out a couple of air voids then we should start laying up the part.

Something I'm torn over.... Maybe you guys could offer opinions. Thinking of adding a 19" square glass viewing window on the front of the corner bait tanks. The baitwell lids will be solid painted fiberglass.

The cost to add the glass viewing windows will add approx $600 to the project. My brother thinks we shouldn't do them, I really like the idea of having them.

Even if just hanging at the dock with the kiddos, let them put pinfish, crabs, whatever in the tanks, turn on the baitwell underwater lights and they have a fish tank to watch/play with.

Thoughts?