Why I'm Not Going To The Airshow This Weekend.

Well, since everybody else seems to have cool boating projects going on I thought I'd resurrect this thread to prove that I still work on my own boat. I never seem to get to use it, but I do seem to work on it a lot.

I guess I probably should have looked into the injection pumps a long time ago. However I'm not really that excited to add more work to the to-do list, so I thought if they ain't broke.... Well, one of them broke. And like shoes you don't buy just one.

Since I have a connection at a fuel injection shop I had the opportunity to rebuild these myself, and in the rich tradition of yachtsmanbill I took pictures. So I thought I'd share something of the mysterious "dark art" of fuel injection with the HOF.

This wasn't the one that was acting up, but it managed to create its own set of problems. It was stuck in the engine and I kept breaking the puller bolts trying to separate it from the drive gear.

So here's "Trick of the trade" #1: The tapered drive is actually a sleeve that is pressed onto the camshaft and by threading a bolt into it you can force it off the pump. After that it popped right out of the gear. In this pic you can see the old sleeve with the forcing bolt still in it on the vise, and the splined end of the camshaft that it is pressed onto. Be careful not to strip the threads in the sleeve, but otherwise don't worry about damaging the sleeve, they're a one-shot deal and get replaced anyway.

Once you get all of it apart you start cleaning. Governor housings before and after. All that varnish is mostly a product of sitting around. So who still thinks you don't need an additive with a cleaning agent?

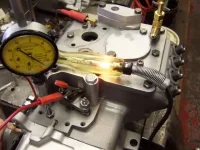

"While we're in there" we might as well do some updates. This pic shows the back flange of the camshaft and the thrust area in the pump housing where it rides.

Arrrghhh! 4 image limit. To be continued...…

***Site only allows 3 uploaded images vs 4 hosted. Working on a solution for that.***