Angela

Legendary Member

- Joined

- Jul 8, 2005

- Messages

- 3,879

- Status

- OWNER - I own a Hatteras Yacht

- Hatteras Model

- 58' MOTOR YACHT-Series I (1977 - 1980)

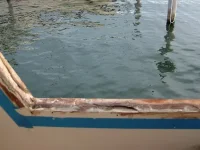

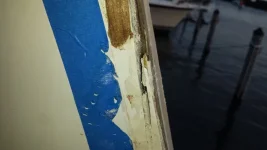

Ed and I have searched for the forum, and read all of the applicable threads, and we are stuck. We are trying to remove a window frame that has proven to be the one of two sources of leaking water down inside the aft deck wall and into the master stateroom below. We can’t fix the interior teak plywood wall until we fix the leak.

We have removed the exterior screws. We have removed the interior teak trim to expose the crevice and dug out all of the caulk. What we cannot do is get a scraper underneath the exterior trim/flange which is where I believe we are stuck. We have tried a heat gun, but the surface is too large. By the time we make a reasonable run with the heat gun, the area where we started is not hot anymore, and we cannot simply pick up a corner and start pulling. This thing will not budge. Is there some technique that we’re missing? Pascal offered us a jack hammer last night, but we declined. We are reserving judgment on that offer, now.

We have removed the exterior screws. We have removed the interior teak trim to expose the crevice and dug out all of the caulk. What we cannot do is get a scraper underneath the exterior trim/flange which is where I believe we are stuck. We have tried a heat gun, but the surface is too large. By the time we make a reasonable run with the heat gun, the area where we started is not hot anymore, and we cannot simply pick up a corner and start pulling. This thing will not budge. Is there some technique that we’re missing? Pascal offered us a jack hammer last night, but we declined. We are reserving judgment on that offer, now.