bobk

Legendary Member

- Joined

- Aug 27, 2005

- Messages

- 4,097

- Status

- OWNER - I own a Hatteras Yacht

- Hatteras Model

- 48' MOTOR YACHT-Series I (1981 - 1984)

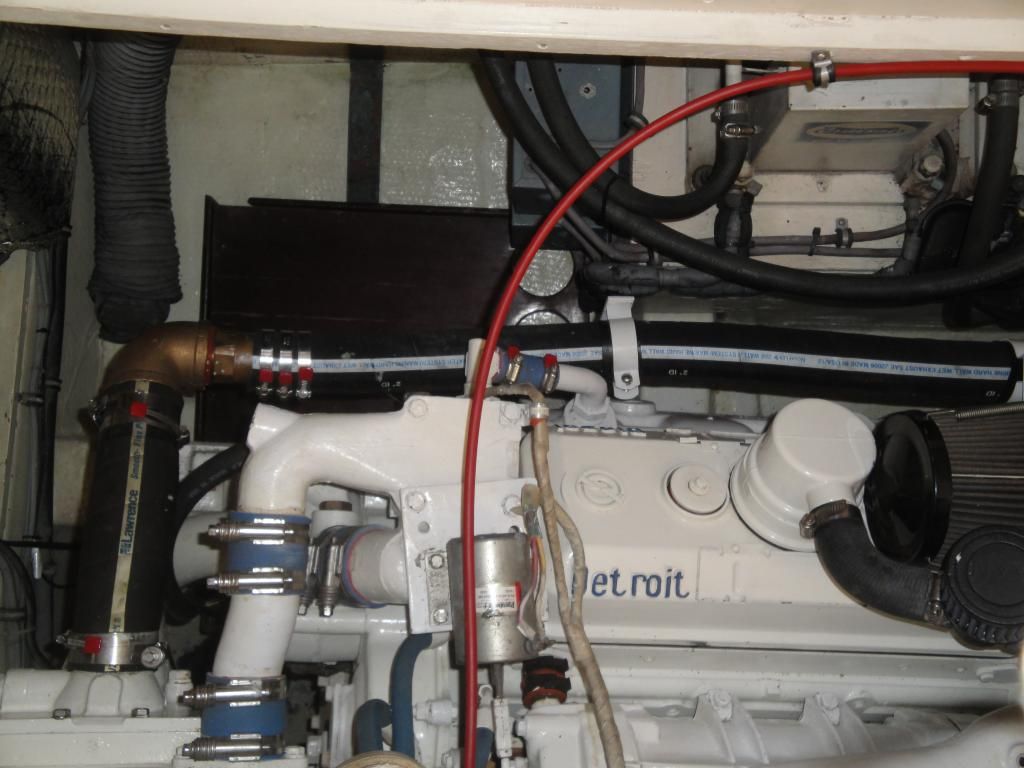

The copper raw water pipe leaving the heat exchanger on the starboard 6V92TA has perforated from corrosion. Can any one recommend a repair shop near Stuart or Port St Lucie FL that could braze it or replace a section? I'm assuming replacing the whole pipe on a 1980 engine will be problematic or very expensive.

Bobk

Bobk