dar636

Well-known member

- Joined

- Feb 19, 2016

- Messages

- 276

- Status

- OWNER - I own a Hatteras Yacht

- Hatteras Model

- 58' YACHT FISHERMAN (1970 - 1981)

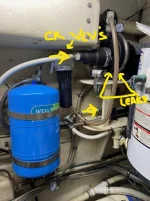

So I have a couple of questions. This is how the water system has been plumbed since I have had the boat. I've only been using the 32v pump as the 120v was leaking out of the diaphragm when I took the boat. I replaced the 120v pump and it immediately blew out and leaked again from the diaphragm I think from back pressure when the 32v pump operates.

I think that to be able to use the pumps as plumbed there needs to be a check valve in the outlet of each pump so that when the other operates pressure does not go back into the non-running pump, which in the case of the 120v pump seems to be fatal.

The yellow highlighted pic shows the system with the 'Y' valves positioned for operating the 32v pump.

The blue highlighted pic shows the flow when the 120v pump would run BUT the 'Y' vales aren't positioned... its the only pic I had.

First question is how am I supposed to be using the system? Manually turn on whatever pump I intend to use and position the valves accordingly?

Or leave them both ON and whichever one has power would run? How would I position the 'Y' valves? Manually again?

Frankly I could probably live without the 120v pump as the 32v works well enough including deck washing.

Any comments or suggestions? Thanks-

I think that to be able to use the pumps as plumbed there needs to be a check valve in the outlet of each pump so that when the other operates pressure does not go back into the non-running pump, which in the case of the 120v pump seems to be fatal.

The yellow highlighted pic shows the system with the 'Y' valves positioned for operating the 32v pump.

The blue highlighted pic shows the flow when the 120v pump would run BUT the 'Y' vales aren't positioned... its the only pic I had.

First question is how am I supposed to be using the system? Manually turn on whatever pump I intend to use and position the valves accordingly?

Or leave them both ON and whichever one has power would run? How would I position the 'Y' valves? Manually again?

Frankly I could probably live without the 120v pump as the 32v works well enough including deck washing.

Any comments or suggestions? Thanks-