Sam's is your source for Hatteras and Cabo Yacht parts.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Onan Mdjf 15kw generator

- Thread starter rcarter

- Start date

- Replies 11

- Views 3,277

rcarter

Member

- Joined

- Sep 29, 2017

- Messages

- 20

- Status

- OWNER - I own a Hatteras Yacht

- Hatteras Model

- 48' COCKPIT MY-Series I (1981 - 1983)

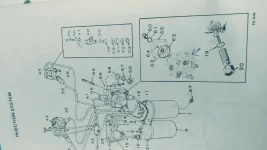

Injection pump American bosch type PSUHas anyone tried to rebuild the fuel injection pump, mine has a small fuel leakat the front of the pump.

Attachments

rcarter

Member

- Joined

- Sep 29, 2017

- Messages

- 20

- Status

- OWNER - I own a Hatteras Yacht

- Hatteras Model

- 48' COCKPIT MY-Series I (1981 - 1983)

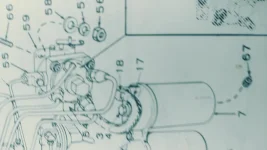

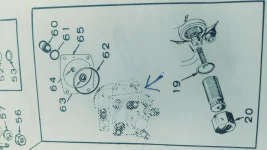

Under the bottom of the pump. Look at photo of the parts book, I drew a arrow where the leak appears.I'm thinking it may be the O-ring leaking. Hopefully you can make out the photos I sent.

Attachments

Avenger

Legendary Member

- Joined

- Jun 23, 2005

- Messages

- 5,160

- Location

- LI - NY

- Status

- OWNER - I own a Hatteras Yacht

- Hatteras Model

- 36' CONVERTIBLE-Series I (1969 -1977)

They all leak from the bottom. Because, you know, gravity.

I would try to clean the whole thing thoroughly with Brakleen or some other solvent and compressed air and get it bone dry to verify where the leak is coming from. Hopefully you can avoid disassembling more than is absolutely necessary.

The most likely leak points are the O-rings that seal the distributor head to the housing, or the control shaft.

It shouldn't be too difficult, depending on your mechanical skills, to remove the head and replace the O-rings. The trickiest part of reassembly is getting the control shaft correctly aligned with the internal sleeve that controls fuel delivery.

If you intend to remove the head from the pump, you should probably loosen the head retaining screws (26) before you remove the pump from the engine. The pump shouldn't be clamped in a vise, so the engine will make the best holder for you.

Follow the timing procedure for aligning the pump with the timing pin before removing the pump so you can reinstall it without excessive heartburn. Also, I cannot stress cleanliness enough. Fuel injection does not like dirt, paint chips or any other contaminants. So have a clean work area and clean, lint-free rags. Compressed air is also a wonderful thing as long as you're careful with it and don't blow parts away.

Once the pump is out follow below as necessary. If you're lucky it's only the control shaft O-ring and you can avoid messing with the head.

Remove the screws (3) that secure the control shaft retainer (11) and pull out the control shaft (8). Do not lose the pin (8A). Then remove the head locating screw (42). Remove the head retaining screws and clamps (26/27). Lift entire head assembly out of housing. That's everything between the tappet (16) and the delivery valve holder (29) including the gear. DO NOT attempt to disassemble the head. Catastrophic things will happen if it is not reassembled correctly.

Change O-rings 28, 28A & 12. Reassembly is pretty much reverse of disassembly except when you reinstall the head, immediately install the locating screw to align it properly. And when you reinstall the control shaft the flat on the pin must fit in the groove of the control sleeve *visible in the slot in the head assy. and through the control shaft bore. If installed correctly the shaft will spin 360°. Once you verify that you can reinstall the retaining plate. Once the pump is back on the engine torque the head clamps to 13-15 lb/ft.

I would try to clean the whole thing thoroughly with Brakleen or some other solvent and compressed air and get it bone dry to verify where the leak is coming from. Hopefully you can avoid disassembling more than is absolutely necessary.

The most likely leak points are the O-rings that seal the distributor head to the housing, or the control shaft.

It shouldn't be too difficult, depending on your mechanical skills, to remove the head and replace the O-rings. The trickiest part of reassembly is getting the control shaft correctly aligned with the internal sleeve that controls fuel delivery.

If you intend to remove the head from the pump, you should probably loosen the head retaining screws (26) before you remove the pump from the engine. The pump shouldn't be clamped in a vise, so the engine will make the best holder for you.

Follow the timing procedure for aligning the pump with the timing pin before removing the pump so you can reinstall it without excessive heartburn. Also, I cannot stress cleanliness enough. Fuel injection does not like dirt, paint chips or any other contaminants. So have a clean work area and clean, lint-free rags. Compressed air is also a wonderful thing as long as you're careful with it and don't blow parts away.

Once the pump is out follow below as necessary. If you're lucky it's only the control shaft O-ring and you can avoid messing with the head.

Remove the screws (3) that secure the control shaft retainer (11) and pull out the control shaft (8). Do not lose the pin (8A). Then remove the head locating screw (42). Remove the head retaining screws and clamps (26/27). Lift entire head assembly out of housing. That's everything between the tappet (16) and the delivery valve holder (29) including the gear. DO NOT attempt to disassemble the head. Catastrophic things will happen if it is not reassembled correctly.

Change O-rings 28, 28A & 12. Reassembly is pretty much reverse of disassembly except when you reinstall the head, immediately install the locating screw to align it properly. And when you reinstall the control shaft the flat on the pin must fit in the groove of the control sleeve *visible in the slot in the head assy. and through the control shaft bore. If installed correctly the shaft will spin 360°. Once you verify that you can reinstall the retaining plate. Once the pump is back on the engine torque the head clamps to 13-15 lb/ft.

Avenger

Legendary Member

- Joined

- Jun 23, 2005

- Messages

- 5,160

- Location

- LI - NY

- Status

- OWNER - I own a Hatteras Yacht

- Hatteras Model

- 36' CONVERTIBLE-Series I (1969 -1977)

You certainly can. I'm not sure if you'll have enough room to do it on the engine, because you're going to need to rotate the control lever 360° to confirm that it's installed correctly. Also, getting the pin aligned with the control sleeve while it's vertical may be a challenge. I would recommend pulling the pump for this procedure. But there's no reason to go any deeper into the pump than necessary.