neildeb2

Active member

- Joined

- Apr 9, 2021

- Messages

- 74

- Status

- OWNER - I own a Hatteras Yacht

- Hatteras Model

- 58' LRC (1975 - 1981)

Hi all,

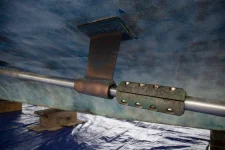

Our 58LRC has the 2-prt hafts. I dove on her to replace zincs and discovered a couple of the bolts clamping the muff couplers together. Can anyone help me with answers to the following questions?

1. What size/spec bolts and nuts do I buy to replace them?

2. How is it that bronze muff couplers can bolt to stainless shafts without dissimilar metal corrosion?

3. Similarly, how do SS bolts not produce dissimilar metal corrosion (or is this perhaps why the bolts are missing?)

4. Has anyone else had this happen to them?

Thx,

Neil

Our 58LRC has the 2-prt hafts. I dove on her to replace zincs and discovered a couple of the bolts clamping the muff couplers together. Can anyone help me with answers to the following questions?

1. What size/spec bolts and nuts do I buy to replace them?

2. How is it that bronze muff couplers can bolt to stainless shafts without dissimilar metal corrosion?

3. Similarly, how do SS bolts not produce dissimilar metal corrosion (or is this perhaps why the bolts are missing?)

4. Has anyone else had this happen to them?

Thx,

Neil