rsmith

Legendary Member

- Joined

- Mar 21, 2010

- Messages

- 6,322

- Status

- OWNER - I own a Hatteras Yacht

- Hatteras Model

- 50' CONV -Series I (1966 - 1969)

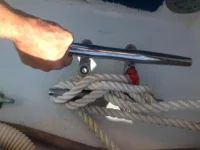

Ok so after surviving the 04 hurricanes I came to the conclusion that I needed larger cleats. I have always double lines the boat if I'm gone for any period of time. During France's and jeane I watched brand new 3/4" lines saw through chafing gear and the line in about an hour of 100mph winds.

I bought some monster cleats from SAMs and have had them sitting in the shop since. The Hatt stern cleat mounting has never failed but I'm not real happy abought the gap between the cockpit liner and the hull. Seems there is about 3/4" of air there. If you don't use cap nuts to bottom the bolts the liner bends inward and distorts. I thought about sliding a piece of starboard but its not easy to get up in there and I still don't think it will make a tight "sandwich" other than the hole saw fill and redrill any ideas?

I bought some monster cleats from SAMs and have had them sitting in the shop since. The Hatt stern cleat mounting has never failed but I'm not real happy abought the gap between the cockpit liner and the hull. Seems there is about 3/4" of air there. If you don't use cap nuts to bottom the bolts the liner bends inward and distorts. I thought about sliding a piece of starboard but its not easy to get up in there and I still don't think it will make a tight "sandwich" other than the hole saw fill and redrill any ideas?