danshat

Active member

- Joined

- Jun 16, 2007

- Messages

- 143

- Status

- OWNER - I own a Hatteras Yacht

- Hatteras Model

- 34' DOUBLE CABIN (1963 - 1966)

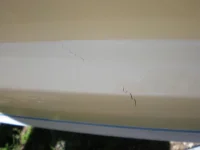

Ok so upon recommendation of the local boat expert (yeah right) I had splash rails made out of oak and installed (obviously without a level.) I followed all of his instructions about how long to wait before painting them etc. The bottom half of the boat was painted a while ago and now I'm not happy. I hate bothering you guys but does anyone have any suggestions as to how I can fix this now?