dar636

Well-known member

- Joined

- Feb 19, 2016

- Messages

- 276

- Status

- OWNER - I own a Hatteras Yacht

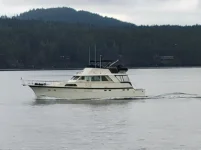

- Hatteras Model

- 58' YACHT FISHERMAN (1970 - 1981)

Hello,

Well the rains are back in force in the great NW, the YF has developed a leak I assume from the flybridge hold down screws into coring, and its coming out of the port side pilothouse door extrior light. Real ugly brown/red stains.

Is the fix to rebed all of the screws? Is there a better way? How is it done?

Well the rains are back in force in the great NW, the YF has developed a leak I assume from the flybridge hold down screws into coring, and its coming out of the port side pilothouse door extrior light. Real ugly brown/red stains.

Is the fix to rebed all of the screws? Is there a better way? How is it done?