Genevatexan

Active member

- Joined

- Apr 12, 2010

- Messages

- 111

- Status

- OWNER - I own a Hatteras Yacht

- Hatteras Model

- Not Currently A Hatteras Owner

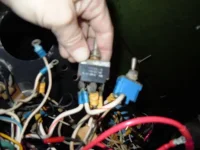

My flybridge guage panel was metal and the Stewart Warner gauges oxidized and failing. I had a new panel made by a guy that does Sea Ray panels with a CNC router out of the black material with routed white letters. That panel has rectangular 1.450 x .83 cutouts and he provided some Carling contour switches formerly used by Sea Ray. The panel maker included SPST switches on everything but the starter switches, which came as SPST Mo-On, Off.

Three questions: 1) the starter switch needs to Mo-on/Off/M-on to activate the stop solenoid in the aft M-on position. But must it be Dual Pole, or Single Pole? (Is the presence of two terminals in the middle of the switch indication that it is dual pole?) 2) the Carling/Sea Ray switches he sent are all 20 amp but do any need to be any stronger (starter switches?) 3) His switches are all straight 1/4 spade lugs-no screws. My old set are all screw terminals. It makes me nervous to install non screw down connections, and I worry about them bounding loose. Can you buy contour switches with screw terminals today? I also do not relish cutting off about 1/2 inch of every wire under the helm to replace the ends and maybe degrade the strenth and reilability of the conttetion...

Kent

Three questions: 1) the starter switch needs to Mo-on/Off/M-on to activate the stop solenoid in the aft M-on position. But must it be Dual Pole, or Single Pole? (Is the presence of two terminals in the middle of the switch indication that it is dual pole?) 2) the Carling/Sea Ray switches he sent are all 20 amp but do any need to be any stronger (starter switches?) 3) His switches are all straight 1/4 spade lugs-no screws. My old set are all screw terminals. It makes me nervous to install non screw down connections, and I worry about them bounding loose. Can you buy contour switches with screw terminals today? I also do not relish cutting off about 1/2 inch of every wire under the helm to replace the ends and maybe degrade the strenth and reilability of the conttetion...

Kent