racclarkson@gmail.com

Legendary Member

- Joined

- Aug 6, 2015

- Messages

- 3,722

- Status

- OWNER - I own a Hatteras Yacht

- Hatteras Model

- 55' CONV -Series I (1979 - 1988)

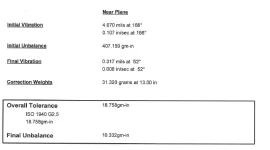

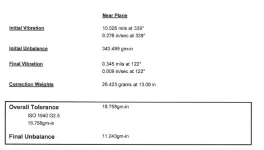

Getting ready to bust my port shaft loose from the ZF gear check out some vibration. I'm kinda pleased with this. I made extensions that'll allow measurements to be taken at the coupling, hub and the shaft all the way back to the dripless seal.

I use a C-clamp to secure the legs to the transverse stringer.

This seems to work better than the vice-grip type mounts because it's rigid.

I use a C-clamp to secure the legs to the transverse stringer.

This seems to work better than the vice-grip type mounts because it's rigid.