rustybucket

Legendary Member

- Joined

- Jul 12, 2013

- Messages

- 1,200

- Status

- OWNER - I own a Hatteras Yacht

- Hatteras Model

- 52' CONVERTIBLE (1983 - 1990)

Hello all, i've tried to register over at marineac.com to ask these questions on the forums there but can't seem to get registered for it, so I'm going to post them here.

Basically I'm trying to go through our AC/Heat systems and repair/fix/learn about them. My goal is to become knowledgeable enough to service/repair them myself. Not so much b/c I want to save money, more about being able to fix/repair them when we are in remote locations and no repair people are available.

So, to start I'm pretty much ignorant on this subject lol. I've been reading quite a bit about marine ac systems so I think I kinda have my mind wrapped around the concepts involved.

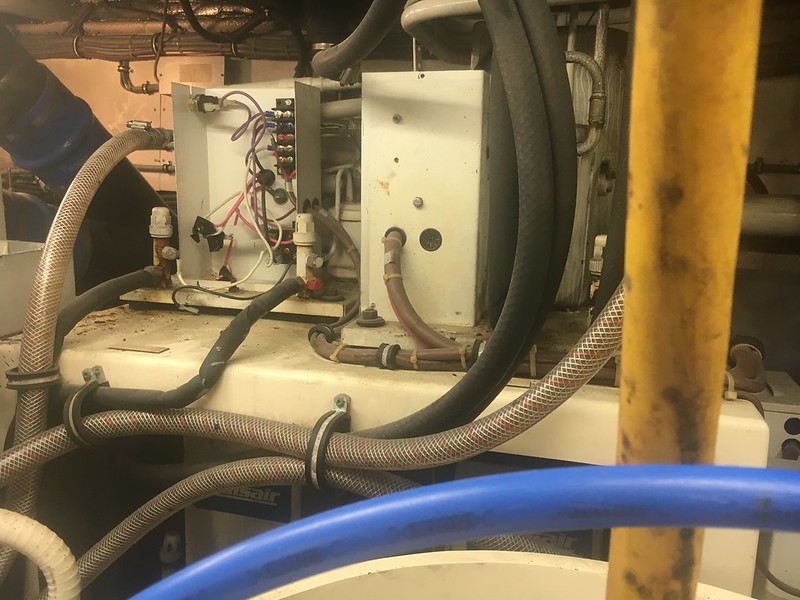

To start, we have 4 cruisair systems on our 1986 52c. 3 appear to the be the same size and service all 3 staterooms. And one unit serves the main salon and galley.

I do know that the master stateroom system appears to be working properly. It will cool/heat the master stateroom fairly well.

I do also know that there are capacitors and possibly a relay missing out of at least one of the other stateroom units.

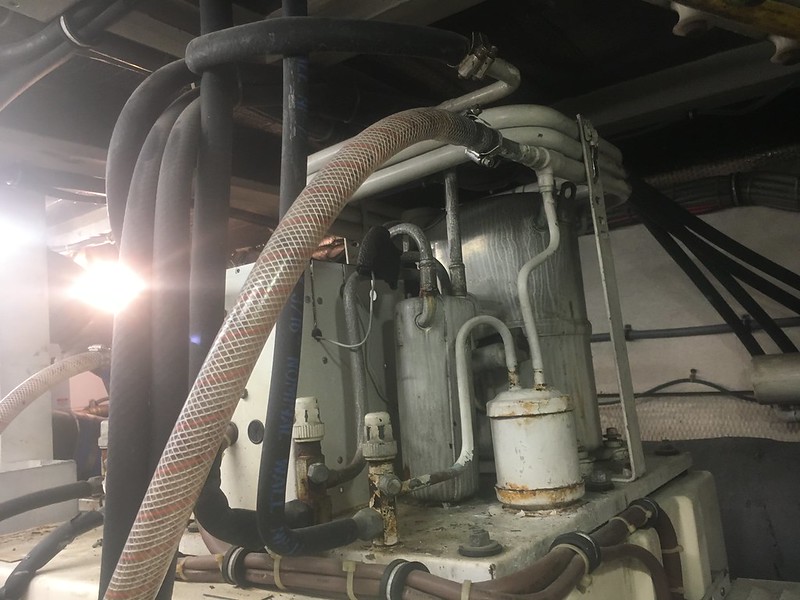

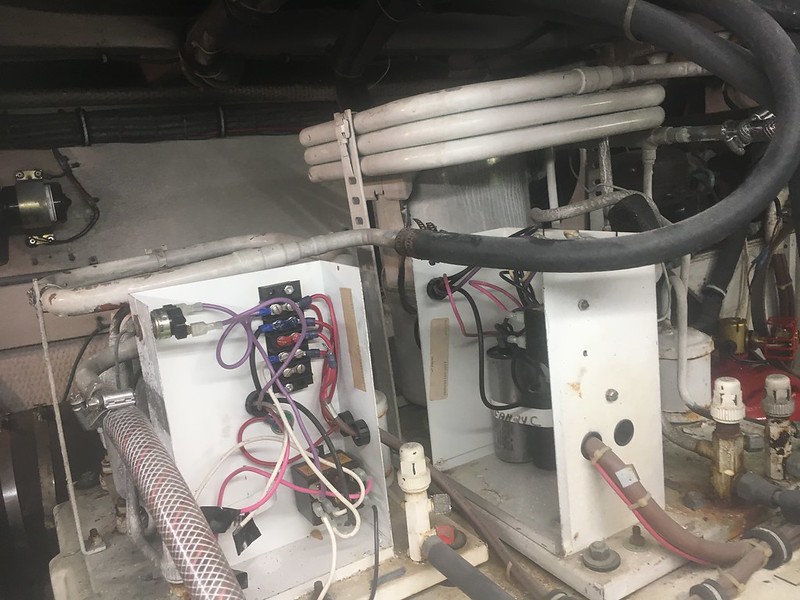

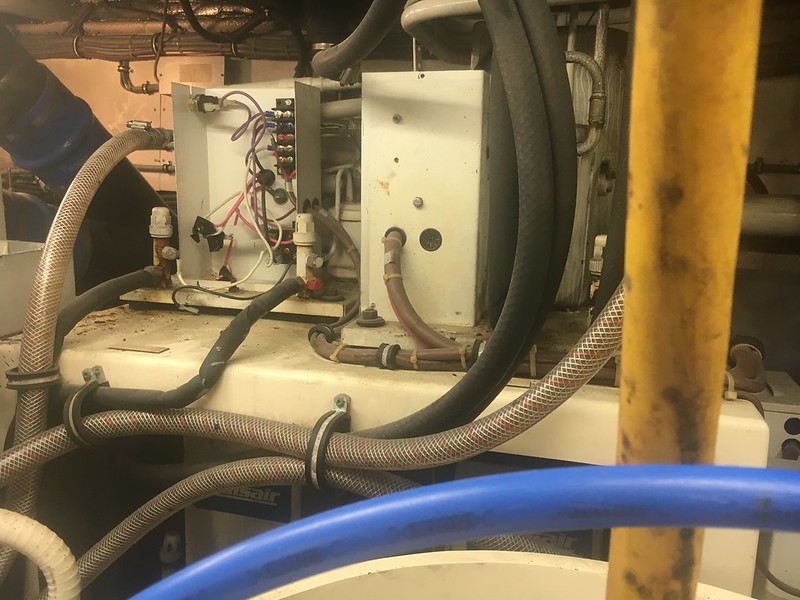

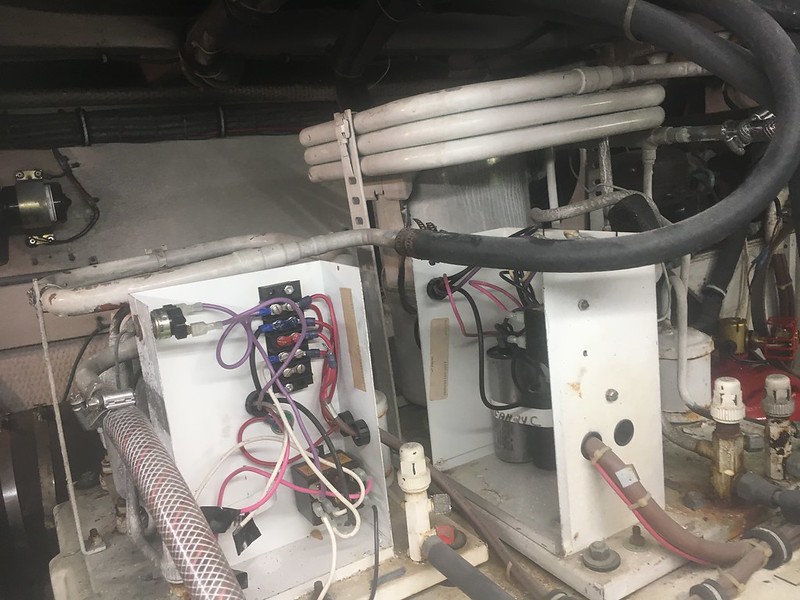

You can see the unit on the left (one of the staterooms) here missing capacitors.

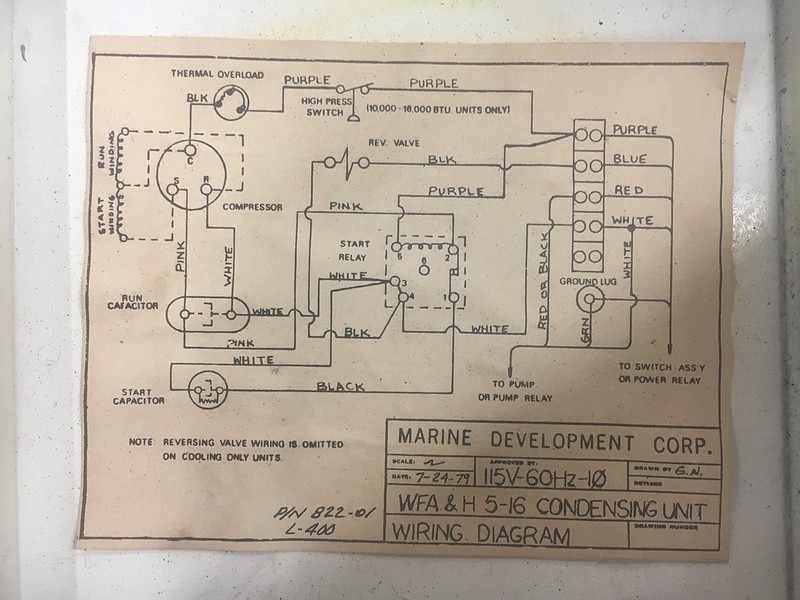

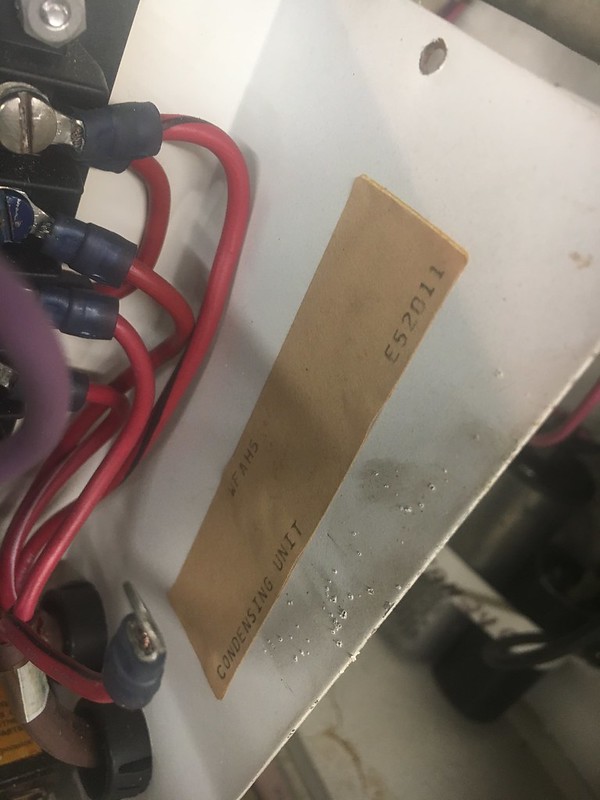

So I guess my first question, anyone happen to know what size units these may be? Also, what size capacitors go into these units?

Here are some pics that may help with identification.

Basically I'm trying to go through our AC/Heat systems and repair/fix/learn about them. My goal is to become knowledgeable enough to service/repair them myself. Not so much b/c I want to save money, more about being able to fix/repair them when we are in remote locations and no repair people are available.

So, to start I'm pretty much ignorant on this subject lol. I've been reading quite a bit about marine ac systems so I think I kinda have my mind wrapped around the concepts involved.

To start, we have 4 cruisair systems on our 1986 52c. 3 appear to the be the same size and service all 3 staterooms. And one unit serves the main salon and galley.

I do know that the master stateroom system appears to be working properly. It will cool/heat the master stateroom fairly well.

I do also know that there are capacitors and possibly a relay missing out of at least one of the other stateroom units.

You can see the unit on the left (one of the staterooms) here missing capacitors.

So I guess my first question, anyone happen to know what size units these may be? Also, what size capacitors go into these units?

Here are some pics that may help with identification.

Last edited: