Vincentc

Legendary Member

- Joined

- Jun 3, 2008

- Messages

- 1,514

- Status

- OWNER - I own a Hatteras Yacht

- Hatteras Model

- 43' DOUBLE CABIN (1970 - 1984)

Since I am now reporting and recording what I am doing rather than asking for advice I thought I would start a new thread with a more descriptive title. This is a continuation of the thread:

http://www.samsmarine.com/forums/showthread.php?20256-Aft-Deck-Sag-Problem

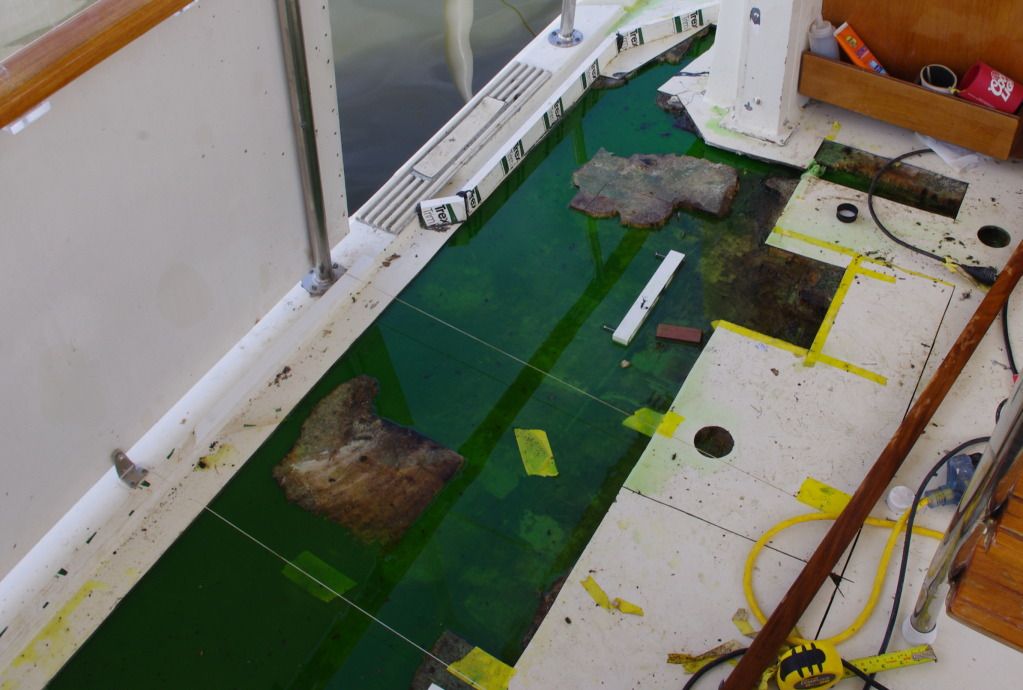

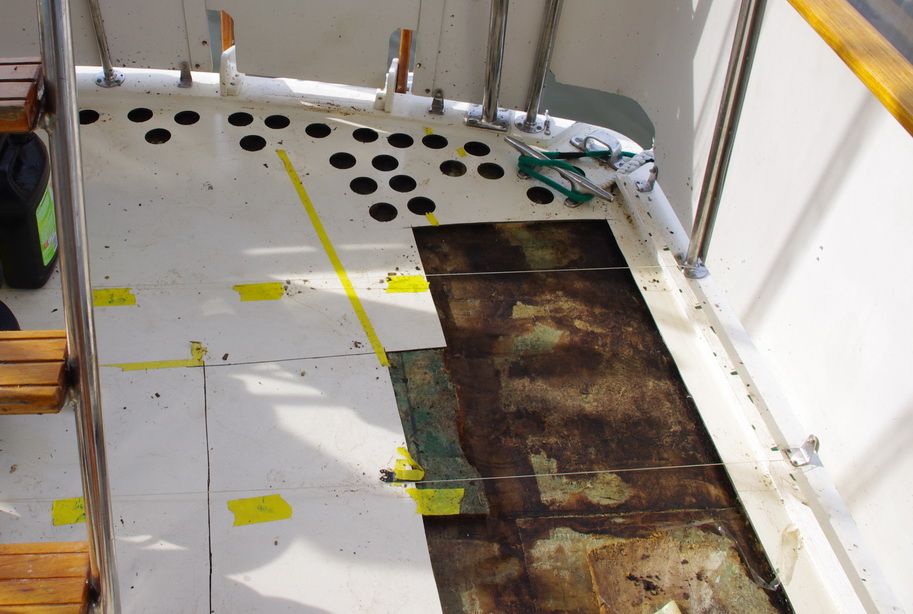

The bad balsa coring extends into areas I did not expect and as I followed the rotten balsa I decided to use a 2.5" hole saw and have since learned that the multi-tool works well in removing bad coring surrounding the hole and I can go out about 1.25 inches out from the perimeter of the hole with the blade. I will post pictures later as I came to the house for lunch and left the camera on the boat.

My plan is to track down the rot, remove it and clean the area with a shop vac. Once it is clean and reasonably dry, I will flood the area with ethylene glycol (anti-freeze) to kill the rot,

see:

http://www.angelfire.com/nc3/davecarnell/rot.html

then vacuum the area and let it air dry. I will fill the voids with plywood and filled epoxy. Areas under the hole saw opening will not be accessible to plywood. I have ordered 6 gallons of RAKA epoxy and several pounds of filler.

Although I have decided on a plan, any suggestions will still be welcome.

To be continued

http://www.samsmarine.com/forums/showthread.php?20256-Aft-Deck-Sag-Problem

The bad balsa coring extends into areas I did not expect and as I followed the rotten balsa I decided to use a 2.5" hole saw and have since learned that the multi-tool works well in removing bad coring surrounding the hole and I can go out about 1.25 inches out from the perimeter of the hole with the blade. I will post pictures later as I came to the house for lunch and left the camera on the boat.

My plan is to track down the rot, remove it and clean the area with a shop vac. Once it is clean and reasonably dry, I will flood the area with ethylene glycol (anti-freeze) to kill the rot,

see:

http://www.angelfire.com/nc3/davecarnell/rot.html

then vacuum the area and let it air dry. I will fill the voids with plywood and filled epoxy. Areas under the hole saw opening will not be accessible to plywood. I have ordered 6 gallons of RAKA epoxy and several pounds of filler.

Although I have decided on a plan, any suggestions will still be welcome.

To be continued