jim rosenthal

Super Moderator

- Joined

- Apr 12, 2005

- Messages

- 11,050

- Hatteras Model

- 36' CONVERTIBLE-Series I (1969 -1977)

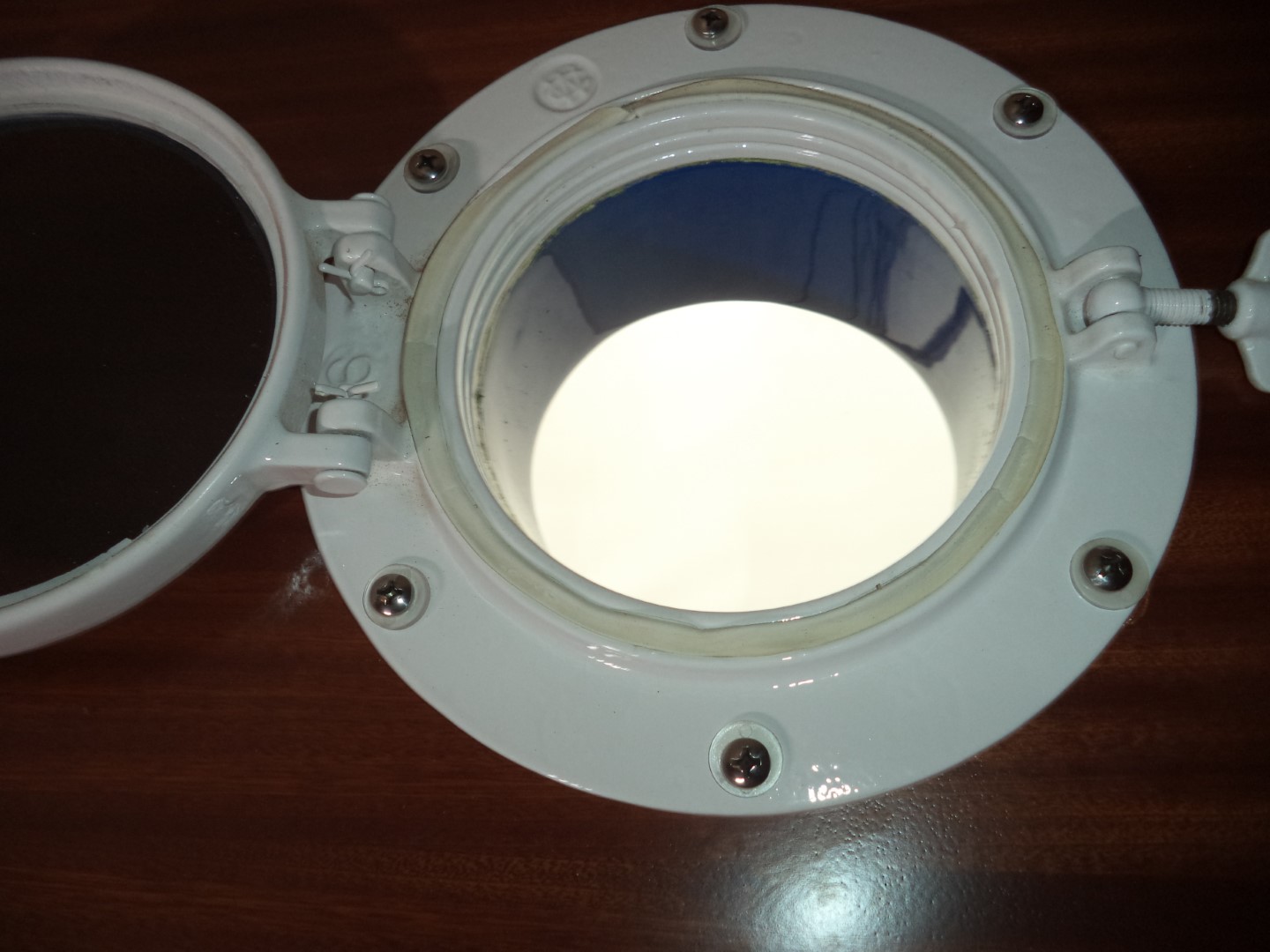

This is an amazing piece of work, the vent tubes. Beautiful.

I have Isspro tachs, four of them, on my boat. Worked perfectly right out of the box. Isspro items in cars, too.

I have Isspro tachs, four of them, on my boat. Worked perfectly right out of the box. Isspro items in cars, too.