Bob Quinn

Legendary Member

- Joined

- Jul 24, 2020

- Messages

- 1,389

- Status

- OWNER - I own a Hatteras Yacht

- Hatteras Model

- 53' MOTOR YACHT (1969 - 1988)

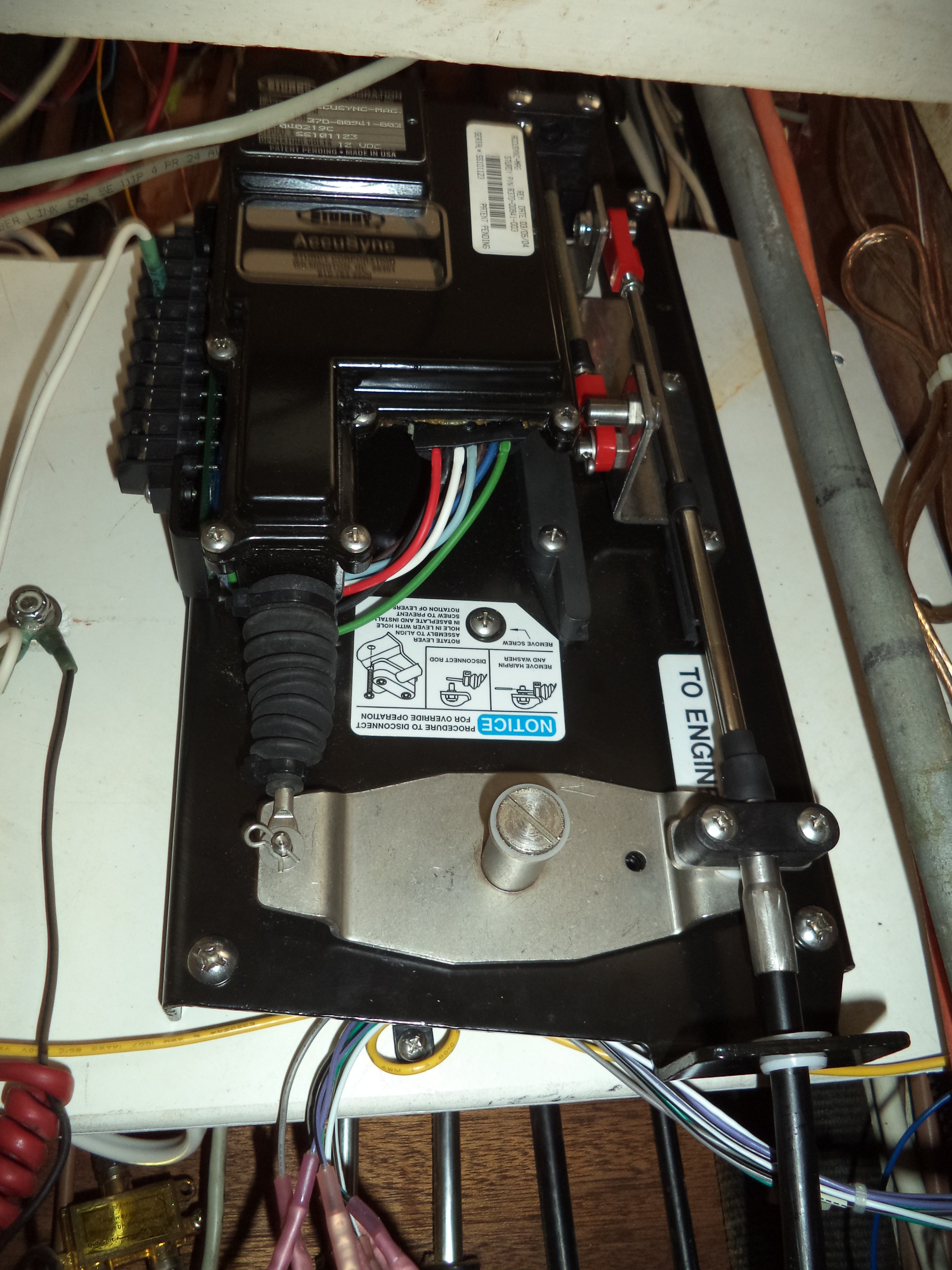

Very nice work! It's almost artwork

Are those all S.S. pipe fittings? If so where did you find them, I have neve seen SS t's and such like that!

Thanks,

Bob

Are those all S.S. pipe fittings? If so where did you find them, I have neve seen SS t's and such like that!

Thanks,

Bob