Sam's is your source for Hatteras and Cabo Yacht parts.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

1969 Chris Craft Roamer 46 refit

- Thread starter q240z

- Start date

- Replies 1,855

- Views 737,937

jim rosenthal

Super Moderator

- Joined

- Apr 12, 2005

- Messages

- 11,050

- Hatteras Model

- 36' CONVERTIBLE-Series I (1969 -1977)

Quentin, I was down in your neck of the woods yesterday, but I couldn't remember which marina your Chris Craft is in. Glad things are looking up for you and I hope you are able to get back on the boat project and complete it- and that we all get to see photos and video of the launch and maiden voyage.

q240z

Legendary Member

- Joined

- Nov 12, 2008

- Messages

- 1,678

- Status

- FRIEND

- Hatteras Model

- Not Currently A Hatteras Owner

Thanks, everybody, for the kind words and encouragement over the years.

That said, his permanent termination from federal service is one of my many settlement demands, and it's in the group we've identified as being non-negotiable.

It really is criminal, though, that taxpayers will have to foot the bill for this corruption. We're subsidizing bad behavior...it's predictable that would lead to there being more of it.

Oh...you have no idea how badly I wanted to add the jerk and a half-dozen corrupt managers to the lawsuit personally. But my lawyer assures me that Congress and the courts have immunized corrupt bureaucrats from being held personally liable for flagrant violations of the law that nobody else is entitled to.OUTSTANDING!!! I only wish the jerk himself had to pay!!!

That said, his permanent termination from federal service is one of my many settlement demands, and it's in the group we've identified as being non-negotiable.

It really is criminal, though, that taxpayers will have to foot the bill for this corruption. We're subsidizing bad behavior...it's predictable that would lead to there being more of it.

q240z

Legendary Member

- Joined

- Nov 12, 2008

- Messages

- 1,678

- Status

- FRIEND

- Hatteras Model

- Not Currently A Hatteras Owner

Thanks!

I've been getting back into the groove with the refit. But I'm finding that in the time I was away from it, I forgot where I put a bunch of tools, parts, and supplies. I spent a half hour sifting through the boat three times, looking for a particular size of cable clamp. I found my stash of clamps, but there were only larger and smaller sizes, not the size I was looking for. It can be very frustrating since I KNOW I've got a bag of that size somewhere.

Anyway, I finally found the clamps and got busy installing my Magnum Energy 2000w inverter charger. That's one thing off the list that's a wrap.

1969 Chris Craft Roamer 46 Refit: Installing the Magnum Energy Inverter/Charger

Cheers,

Q

I've been getting back into the groove with the refit. But I'm finding that in the time I was away from it, I forgot where I put a bunch of tools, parts, and supplies. I spent a half hour sifting through the boat three times, looking for a particular size of cable clamp. I found my stash of clamps, but there were only larger and smaller sizes, not the size I was looking for. It can be very frustrating since I KNOW I've got a bag of that size somewhere.

Anyway, I finally found the clamps and got busy installing my Magnum Energy 2000w inverter charger. That's one thing off the list that's a wrap.

1969 Chris Craft Roamer 46 Refit: Installing the Magnum Energy Inverter/Charger

Cheers,

Q

q240z

Legendary Member

- Joined

- Nov 12, 2008

- Messages

- 1,678

- Status

- FRIEND

- Hatteras Model

- Not Currently A Hatteras Owner

I'm back to wailing away on the Roamer refit, trying to get the boat ready to splash ASAP. Finishing the raw water system for the main engines is a high priority, and one of the things I needed to do was install thru-hulls for raw water tell-tales so I can confirm that the exhaust showerheads are getting good flow when the engines are running. I couldn't find exactly what I needed, so I made them instead using parts that were readily available: 3/4" mushroom thru-hulls in 316 stainless and 5/8" tubing to match what I welded to the showerhead. They turned out pretty good!

1969 Chris Craft Roamer 46 Refit: Making Raw Water Thru-hull Outlets

Cheers,

Q

1969 Chris Craft Roamer 46 Refit: Making Raw Water Thru-hull Outlets

Cheers,

Q

q240z

Legendary Member

- Joined

- Nov 12, 2008

- Messages

- 1,678

- Status

- FRIEND

- Hatteras Model

- Not Currently A Hatteras Owner

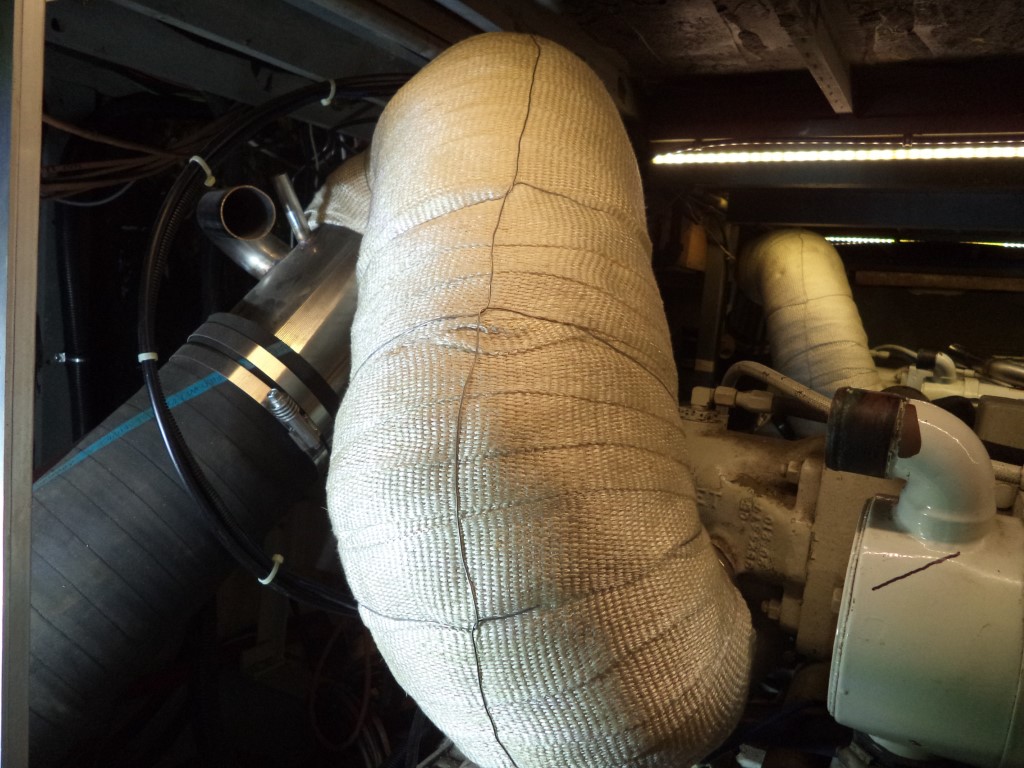

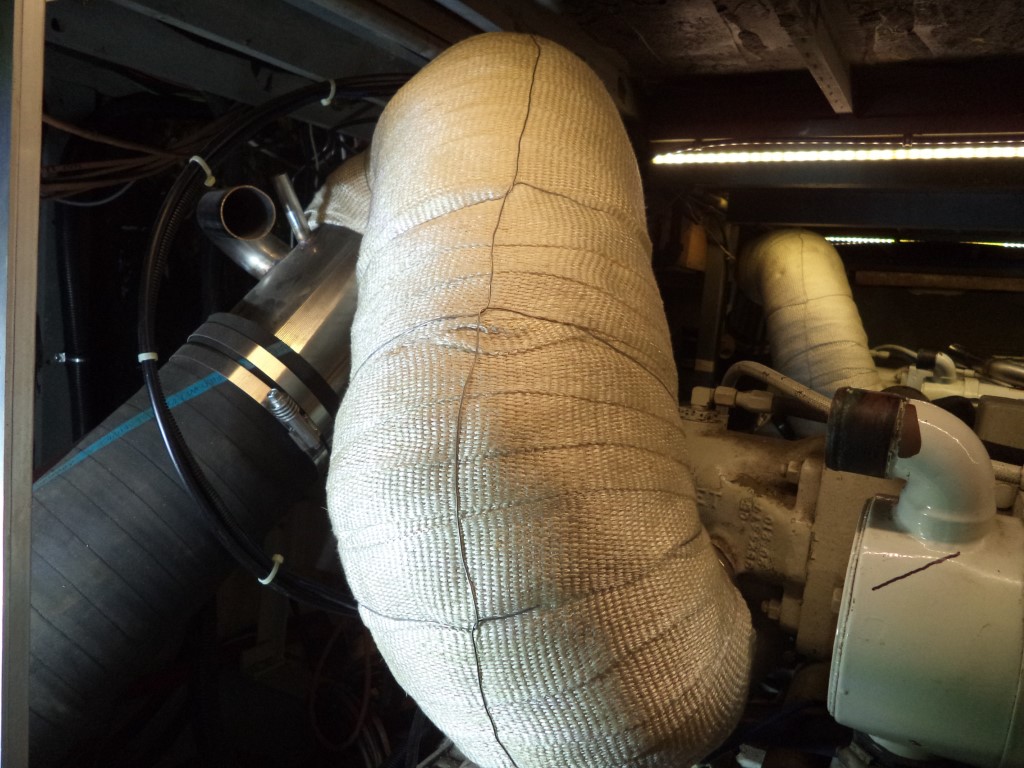

I wrapped up the exhaust end of the main propulsion raw water system by making two pipes I used to connect the raw water outlet from the Cummins heat exchanger to the inlet on the exhaust riser showerhead. The problem was that the HEX outlet pointed directly at the riser and was only 3-1/2" away from it. When I made the risers, I figured I could either find a preformed hose that would route around the riser or I could take the HEXs to the radiator shop and have the outlets reoriented to point toward the showerheads. But I just decided it'd be best to use mandrel-bent stainless tubing and connect the pipes with short sections of 200-series no-wire marine exhaust hose and constant torque clamps.

I also connected the 5/8" raw water outlet at the top of the showerhead to the thru-hull I made recently. That'll divert excess water from having to go through the mufflers and it's nice to have tell-tales to confirm that raw water is flowing properly. All I'll have to do is take three steps from the helm and peek over the safety rail to see if water is squirting out of the thru-hull.

1969 Chris Craft Roamer 46 Refit: Wrapping up the Exhaust Showerhead Plumbing

Cheers,

Q

The problem

The solution

I also connected the 5/8" raw water outlet at the top of the showerhead to the thru-hull I made recently. That'll divert excess water from having to go through the mufflers and it's nice to have tell-tales to confirm that raw water is flowing properly. All I'll have to do is take three steps from the helm and peek over the safety rail to see if water is squirting out of the thru-hull.

1969 Chris Craft Roamer 46 Refit: Wrapping up the Exhaust Showerhead Plumbing

Cheers,

Q

The problem

The solution

jim rosenthal

Super Moderator

- Joined

- Apr 12, 2005

- Messages

- 11,050

- Hatteras Model

- 36' CONVERTIBLE-Series I (1969 -1977)

Beautiful work as always.

Years ago I had a 44' Striker SF which had a telltale system much like that you are doing. They had fitted valves on them, so you could shut the telltales off- I never quite saw the logic in that.

Years ago I had a 44' Striker SF which had a telltale system much like that you are doing. They had fitted valves on them, so you could shut the telltales off- I never quite saw the logic in that.

q240z

Legendary Member

- Joined

- Nov 12, 2008

- Messages

- 1,678

- Status

- FRIEND

- Hatteras Model

- Not Currently A Hatteras Owner

Thanks!

Tony Athens over at Seaboard Marine says you could divert 1/3 of the raw water from your average Cummins' HEX and it would still be more than enough to cool the exhaust. All that added water and vapor just means you have to oversize the exhaust. I could have gone with an even bigger tell-tale to blow more water overboard without going through the muffler, but my calculations are that my muffler/exhaust system can handle the full flow.

Tony Athens over at Seaboard Marine says you could divert 1/3 of the raw water from your average Cummins' HEX and it would still be more than enough to cool the exhaust. All that added water and vapor just means you have to oversize the exhaust. I could have gone with an even bigger tell-tale to blow more water overboard without going through the muffler, but my calculations are that my muffler/exhaust system can handle the full flow.

cww

Well-known member

- Joined

- Jun 3, 2012

- Messages

- 979

- Status

- OWNER - I own a Hatteras Yacht

- Hatteras Model

- 53' MOTOR YACHT (1969 - 1988)

Thanks!

Tony Athens over at Seaboard Marine says you could divert 1/3 of the raw water from your average Cummins' HEX and it would still be more than enough to cool the exhaust. All that added water and vapor just means you have to oversize the exhaust. I could have gone with an even bigger tell-tale to blow more water overboard without going through the muffler, but my calculations are that my muffler/exhaust system can handle the full flow.

The ones that were diesel came this way from the factory. My 47 Commander has side discharges for engine cooling water. It's how Chris-Craft got away with somewhat smaller exhausts than normal. Hatteras just used larger exhausts. They work the same either way.

q240z

Legendary Member

- Joined

- Nov 12, 2008

- Messages

- 1,678

- Status

- FRIEND

- Hatteras Model

- Not Currently A Hatteras Owner

With one end of the raw water system for the mains done, I moved on to the fuel system.

The tanks are in and I roughed out some of the basic plumbing back in 2016, but getting the fuel system done is essential to splash the boat ASAP. While working on the fuel gauge senders, I discovered that rat bastard thieves had siphoned 180 gallons of diesel from one of my tanks. May they rot in hell. Oh, and I discovered that Sunpro sells Made in China junk...I'm sticking with NOS American-made gauges from now on.

Anyway, over the next little while I'll be bending a lot of stainless tubing, getting the aft tank connected to the forward tank, building a valved manifold to control which tanks feed which engine, connecting the mains and genset to the system, and wrapping up the tank connections.

1969 Chris Craft Roamer 46 Refit: The Fuel System

Cheers,

Q

The tanks are in and I roughed out some of the basic plumbing back in 2016, but getting the fuel system done is essential to splash the boat ASAP. While working on the fuel gauge senders, I discovered that rat bastard thieves had siphoned 180 gallons of diesel from one of my tanks. May they rot in hell. Oh, and I discovered that Sunpro sells Made in China junk...I'm sticking with NOS American-made gauges from now on.

Anyway, over the next little while I'll be bending a lot of stainless tubing, getting the aft tank connected to the forward tank, building a valved manifold to control which tanks feed which engine, connecting the mains and genset to the system, and wrapping up the tank connections.

1969 Chris Craft Roamer 46 Refit: The Fuel System

Cheers,

Q

jim rosenthal

Super Moderator

- Joined

- Apr 12, 2005

- Messages

- 11,050

- Hatteras Model

- 36' CONVERTIBLE-Series I (1969 -1977)

Over the last few days, I did an oil change on both my engines, which included repairing the wiring to the oil change pump, and also commissioned the FW system. Today it was 95 degrees out there. I can't believe you are in that tent, that is some dedication.

jim rosenthal

Super Moderator

- Joined

- Apr 12, 2005

- Messages

- 11,050

- Hatteras Model

- 36' CONVERTIBLE-Series I (1969 -1977)

Both days- yesterday and the day before- I came home and realized I had early symptoms of heat exhaustion. You would think as an ER doctor, I would know better. Today I knocked off a lot earlier- and feel a good deal better in the bargain.

Retired1

Well-known member

- Joined

- Dec 4, 2020

- Messages

- 274

- Status

- OTHER

- Hatteras Model

- Not Currently A Hatteras Owner

Both days- yesterday and the day before- I came home and realized I had early symptoms of heat exhaustion. You would think as an ER doctor, I would know better. Today I knocked off a lot earlier- and feel a good deal better in the bargain.

I do a LOT of mountain biking here in Florida (yeah, it’s a thing- YouTube is your friend to see “Airborne Fort Pierce Trail” or “Santos Orlando”) so of course, I’ve heat stroked out dozens of times because it’s sooo humid where there’s no breeze in the summer, and just lay there on the ground waiting to die, but after 15 minutes or so, I make it to my water bottle, and am good to go on -like nothing happened for many miles back to the trailhead . I’ve at least learned now to wait til 6pm to start , when the temperature drops to at least 93 degrees. I no longer ride when it’s 97! Almost died (again) in Sedona!!

Now I’ve recognized a common warning pattern in my thinking that give me a clue when Its soon to happen. When I find myself thinking I’m playing poker, I’ve now learned to dismount, lie down and drink some water. Practice makes perfect.

Last edited:

Boatsb

Senior User

- Joined

- May 4, 2006

- Messages

- 15,229

- Status

- OWNER - I own a Hatteras Yacht

- Hatteras Model

- 41' CONVERTBLE-Series I (1964 - 1971)

I have myself and the crew stop once an hour for water and 5 or so minutes in air conditioning. We go through 10 cases of water a week. Theres 4 of us maximum.

This is not fun but we track urine output and color to keep hydrated and I've not had anyone go down.

This is not fun but we track urine output and color to keep hydrated and I've not had anyone go down.

q240z

Legendary Member

- Joined

- Nov 12, 2008

- Messages

- 1,678

- Status

- FRIEND

- Hatteras Model

- Not Currently A Hatteras Owner

You should see the cobbler's shoes!!!You would think as an ER doctor, I would know better.

I have a buddy who's a master shipwright...does absolutely fabulous wood work. He lives on a boat that's a bloody disaster. Rotten wood and hack repairs everywhere. You'd think he'd know better...and yet... lol

With the fuel gauge and senders working, I got to work on the fuel connections on the Cummins 6CTAs. They originally came with 1/2" 45° flare fittings on the supply side and 5/16" return lines. I swapped that out for 1/2" 37° AN fittings and 3/8 returns, and installed new Type A1 fuel hose as the flexible connection between the engines and the 1/2" and 3/8" stainless tubing I'll be using for supply and returns.

I realize that installing fuel hoses on the engines may not seem like much of an accomplishment, but this was a gas boat. It's never had diesel fuel lines. And once the fuel system is done, there's not a whole lot that needs to be done to get this boat floating.

1969 Chris Craft Roamer 46 Refit: On-Engine Fuel Hoses

Cheers,

Q

q240z

Legendary Member

- Joined

- Nov 12, 2008

- Messages

- 1,678

- Status

- FRIEND

- Hatteras Model

- Not Currently A Hatteras Owner

With the on-engine fuel connections and hoses done, next I assembled and installed the fuel supply distribution manifold. Under normal conditions, each engine will run on its respective tank (stbd-stbd, port-port, genset-fwd), but if I end up with bad fuel in a tank, the manifold will let me run the engines off of any of the three tanks on board.

1969 Chris Craft Roamer 46 Refit: Fuel Supply Manifold

Cheers,

Q

1969 Chris Craft Roamer 46 Refit: Fuel Supply Manifold

Cheers,

Q

Timeless72

Well-known member

- Joined

- Mar 4, 2020

- Messages

- 223

- Status

- OWNER - I own a Hatteras Yacht

- Hatteras Model

- 48' YACHT FISHERMAN (1972 - 1975)

Awesome work! Noticed your screen name. 240z guy? That's my other passion.

Forum statistics

Latest Posts

-

-

Any recent advice on how to retrofit Cruisair Split units

- Started by Cap'n Kirk

- Replies: 7

-

-

-