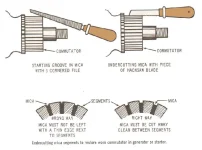

My understanding of rebuilding electric motors includes cutting back the mica spacer bars between the commutator copper bars, ideally a vee shape. without this the mica is at the same height as the commutator copper and glazes the copper leading to arcing etc. I was told this was the reason they didnt bother to rebuild tiny motors as its done in a fixture. that and the motors are sometimes spotwelded together.

Having played with engine starter motors, I understand worn out armatures. Ug

Two over length, thru machine screws go thru these lil DCv motors. Same screws hold the motor to the blower housing or bilge pump frame. With these screws removed, these motors come apart.

I was impressed with the good (near great) condition some armature contacts (commutator fingers) were found when I dissected these motors.

You can tell here where the motor came from;

Blower, very light wear,,

Bilge pump, some wear,,

Pressure water pump, lots of wear and arcing.

With a fine point scribe, a nice groove between the contact fingers can still be felt and cleaned. Thru my many years playing with these things, 50% of the armatures examined got trashed, just because they did not look new.

Not a problem because not all motor cases looked new either.

I used to keep boxes of these things for different applications. IE trim tab pump motors require a split end vs the more common D shape shaft end. Some of the old bellows/diaphragm bilge pumps seemed to assemble better with a longer reach armature/shaft end.

More spares; Reversing motors require a different end cap where the brush holder and pressure springs are riveted in place.

95% of this dust collection went to the scrappers when we moved a few years ago.

I am no expert, just had a lot of fun playing with these lil motors.

Once in a while lucky enough to help somebody out of a jam.

Been keeping my 32V boat going for near 25 years now also.

I am fighting, kicking and screaming but slowly converting to 24V.