rustybucket

Legendary Member

- Joined

- Jul 12, 2013

- Messages

- 1,200

- Status

- OWNER - I own a Hatteras Yacht

- Hatteras Model

- 52' CONVERTIBLE (1983 - 1990)

DIY: Rocket Launcher for fighting chair

Been piddling with this project for a couple months now. Finally got some non-rainy weather to make some progress.

The idea is to take an old fighting chair I had in storage with a ladder back, and convert the back into a rocket launcher with rigging station and some tackle storage.

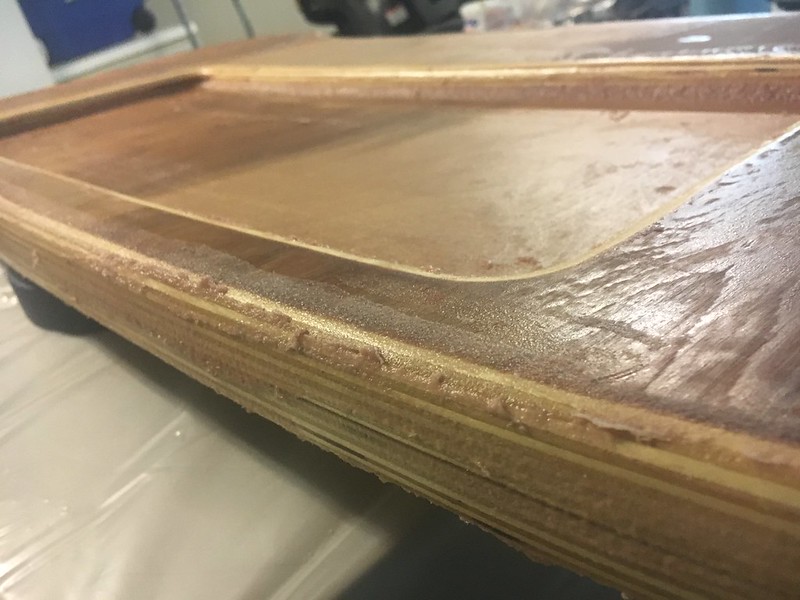

In a perfect world I would have built this out of teak but after searching for teak I decided just to go with a birch plywood and epoxy coating which will be painted.

Some goals

- as many rod holders as possible

- as many cup holders as possible

- as large of a rigging station as possible

- as much tackle storage as possible

- look good

First up, I needed to mock something up. With nothing more than a general idea of what size/shape I wanted this thing I needed to mock up on something cheap. So I chose blue foam insulation at home depot. This was approx $13 for a 4x8 sheet.

Cut up a couple of pieces before I got the general shape I was looking for. Traced and cut out discs to use for rod holders and cupholders

Been piddling with this project for a couple months now. Finally got some non-rainy weather to make some progress.

The idea is to take an old fighting chair I had in storage with a ladder back, and convert the back into a rocket launcher with rigging station and some tackle storage.

In a perfect world I would have built this out of teak but after searching for teak I decided just to go with a birch plywood and epoxy coating which will be painted.

Some goals

- as many rod holders as possible

- as many cup holders as possible

- as large of a rigging station as possible

- as much tackle storage as possible

- look good

First up, I needed to mock something up. With nothing more than a general idea of what size/shape I wanted this thing I needed to mock up on something cheap. So I chose blue foam insulation at home depot. This was approx $13 for a 4x8 sheet.

Cut up a couple of pieces before I got the general shape I was looking for. Traced and cut out discs to use for rod holders and cupholders

Last edited: