- Joined

- Aug 5, 2023

- Messages

- 166

- Status

- OWNER - I own a Hatteras Yacht

- Hatteras Model

- 48' YACHT FISHERMAN (1972 - 1975)

I'm working on replacing some raw water intake hoses that were called out for replacement on my pre-purchase survey. I've run into a bit of a mess on the starboard 8V-71N, surprise surprise..

Yeah.. It was that badly done.

It looks like they went from 2-1/2" Seacock (it may be 3"?) via a threaded pipe nipple coupled to a 3" hose barb, then 3" hose to another barb into another adaptor which reduces to 2-1/2" hose barb to a 2-1/2" hose to the Jabsco pump. The Jabsco pump seems to be around 2-3/4" in diameter and the hose was stretched over it. I assume they used heat to stretch that hose to get it to fit onto the Jabsco inlet.

The port side engine goes straight from the seacock to a barbed adaptor then goes into a 2-1/2" hose directly to the Jabsco pump that it is stretched to fit onto.

That seems like a lot cleaner method than this mess.

Onto the questions...

Is using a 2-1/2" hose and heat stretching it to fit over the Jabsco the correct method?

Or is it better to use 3" hose and clamp it down to the 2-3/4" Jabsco pump fitting, or is clamping the 3" hose down that much not possible ?

The barbed adaptors seem to be available to go directly from (the assumed) 2-1/2" thread to 2-1/2" or 3" hose barbs.

What thread sealant is recommended for the new pipe to barb adaptor I will need to buy to attach directly to the seacock?

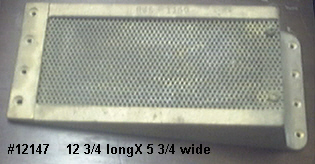

I believe the strainer is a Buck Algonquin - anyone know the thread size on those?

Thanks a million - the tedious journey continues. I'm sure I'll have more threads to start this week.

Yeah.. It was that badly done.

It looks like they went from 2-1/2" Seacock (it may be 3"?) via a threaded pipe nipple coupled to a 3" hose barb, then 3" hose to another barb into another adaptor which reduces to 2-1/2" hose barb to a 2-1/2" hose to the Jabsco pump. The Jabsco pump seems to be around 2-3/4" in diameter and the hose was stretched over it. I assume they used heat to stretch that hose to get it to fit onto the Jabsco inlet.

The port side engine goes straight from the seacock to a barbed adaptor then goes into a 2-1/2" hose directly to the Jabsco pump that it is stretched to fit onto.

That seems like a lot cleaner method than this mess.

Onto the questions...

Is using a 2-1/2" hose and heat stretching it to fit over the Jabsco the correct method?

Or is it better to use 3" hose and clamp it down to the 2-3/4" Jabsco pump fitting, or is clamping the 3" hose down that much not possible ?

The barbed adaptors seem to be available to go directly from (the assumed) 2-1/2" thread to 2-1/2" or 3" hose barbs.

What thread sealant is recommended for the new pipe to barb adaptor I will need to buy to attach directly to the seacock?

I believe the strainer is a Buck Algonquin - anyone know the thread size on those?

Thanks a million - the tedious journey continues. I'm sure I'll have more threads to start this week.

Last edited: