Timm

Active member

- Joined

- May 8, 2007

- Messages

- 163

- Status

- OWNER - I own a Hatteras Yacht

- Hatteras Model

- 53' MOTOR YACHT (1969 - 1988)

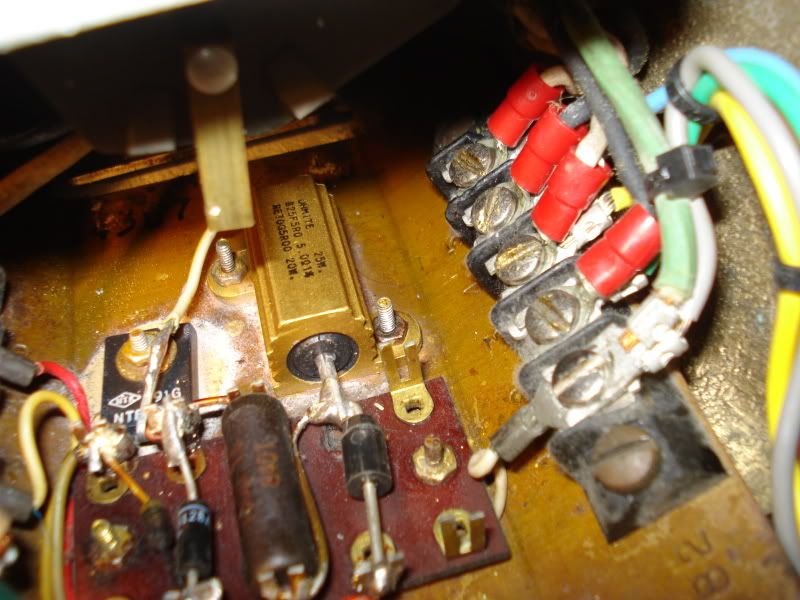

I recently had the original spotlight on a 78' vintage 53' YF rechromed. Prior to disassembly, it worked fine mechanically except the bulb was burned out.

Like a fool, I did not take pictures of the mechanics prior to disassembly.

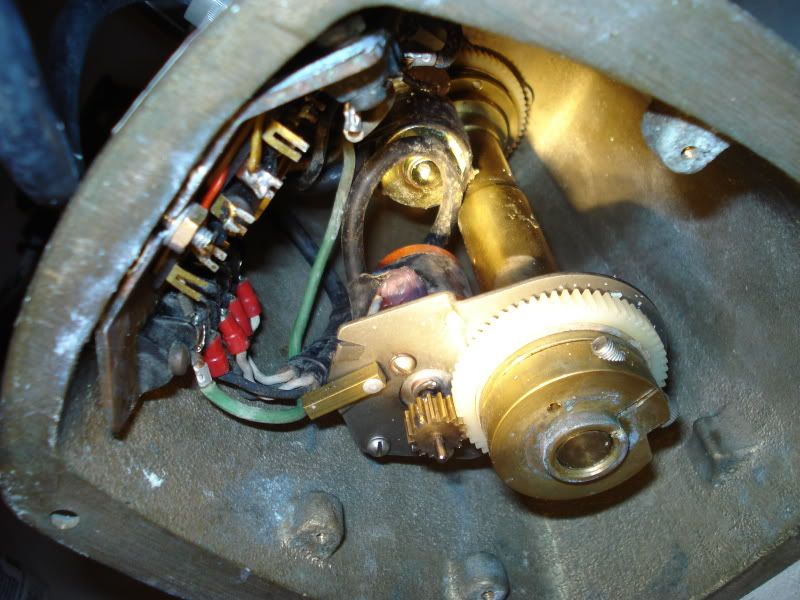

Now, it looks beautiful, lights up fine with a new bulb, but I can't get it to move up/down or right/left. I hear and can see the motors running inside but no actual mechanical movement of the body.

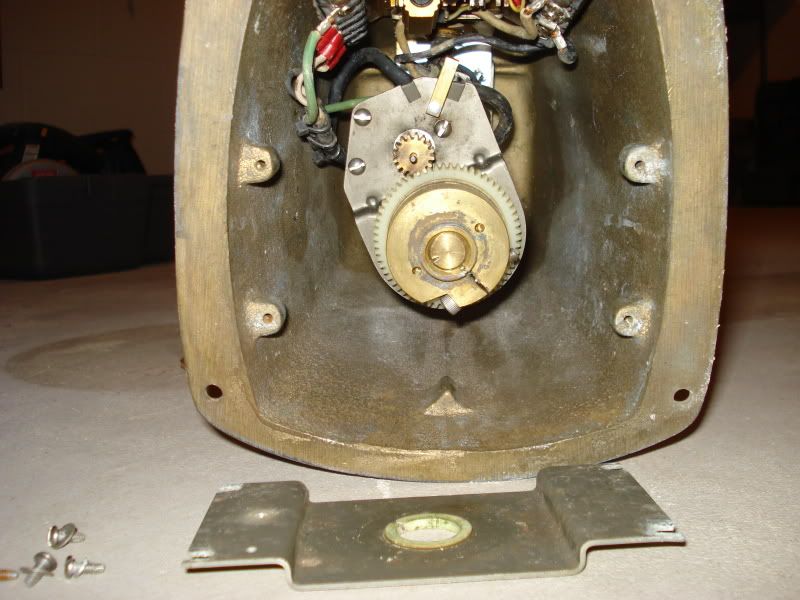

I am wondering if I could ask someone a huge favor if they would be willing to pull their spotlight off of the mounting block attached to the boat, turn it upside down and take a picture of the internal mechanics inside the base and email it to me?

At the very bottom of the base, there is a rectangular plate that has a hole in the center which goes over one of the shafts, mounted with 4 screws on each corner. It would also be very helpful if that person could remove that plate and take an additional picture too.

I'm hoping with pictures of a working light, I can spot something that I may have reassembed incorrectly.

I know this is asking a lot but thought it was worth a shot.

I can be emailed at: timm@walkerairsep.com

Thanks.

Like a fool, I did not take pictures of the mechanics prior to disassembly.

Now, it looks beautiful, lights up fine with a new bulb, but I can't get it to move up/down or right/left. I hear and can see the motors running inside but no actual mechanical movement of the body.

I am wondering if I could ask someone a huge favor if they would be willing to pull their spotlight off of the mounting block attached to the boat, turn it upside down and take a picture of the internal mechanics inside the base and email it to me?

At the very bottom of the base, there is a rectangular plate that has a hole in the center which goes over one of the shafts, mounted with 4 screws on each corner. It would also be very helpful if that person could remove that plate and take an additional picture too.

I'm hoping with pictures of a working light, I can spot something that I may have reassembed incorrectly.

I know this is asking a lot but thought it was worth a shot.

I can be emailed at: timm@walkerairsep.com

Thanks.