Pete

Legendary Member

- Joined

- Apr 12, 2005

- Messages

- 1,167

- Status

- OWNER - I own a Hatteras Yacht

- Hatteras Model

- 48' LRC (1976 - 1981)

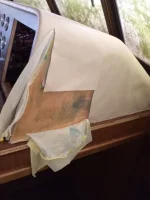

In the early nineties and late eighties, Hatteras covered their raised instrument consoles with a medium beige vinyl material. Per the prior owner, when the lower console was redone in the mid nineties on our 1976 48 LRC, a raised instrument console, manufactured for a 70 motor yacht was installed with this beige vinyl covering. For whatever reason after 20 years that material has lost all it's tension and now looks like a loose fitting cover.

So, it is replacement time, and I am just getting started. At this time I am wondering if anyone in the forum has had experience with this material. It is very thin (.021"), and appears to be a vinyl coating, with a compressed paper backing. Also, appears to have had some stretching characteristics which I am sure aided with the compound curves that are covered.

BTW, it is stapled on the edges with no glue used. Was happy to see that. The recovering job has to be done in place as whoever did the upgrade believed in wood glue. Any info on the material and where some might be found would be appreciated. Did not see anything on SAM'S part list, and he is on my call list next.

Thanks

Pete

So, it is replacement time, and I am just getting started. At this time I am wondering if anyone in the forum has had experience with this material. It is very thin (.021"), and appears to be a vinyl coating, with a compressed paper backing. Also, appears to have had some stretching characteristics which I am sure aided with the compound curves that are covered.

BTW, it is stapled on the edges with no glue used. Was happy to see that. The recovering job has to be done in place as whoever did the upgrade believed in wood glue. Any info on the material and where some might be found would be appreciated. Did not see anything on SAM'S part list, and he is on my call list next.

Thanks

Pete