Starman

Well-known member

- Joined

- Jun 25, 2006

- Messages

- 842

- Hatteras Model

- Not Currently A Hatteras Owner

Somewhere there was a thread about delamination so I thought I would post some pics to show the process for repair.

We had 4 of these spots on the gunnels of Bosslady. As it turns out, these delaminating spots were over some heavy steel plates that I assume were used to pick up the top half of the boat and place it on the hull.

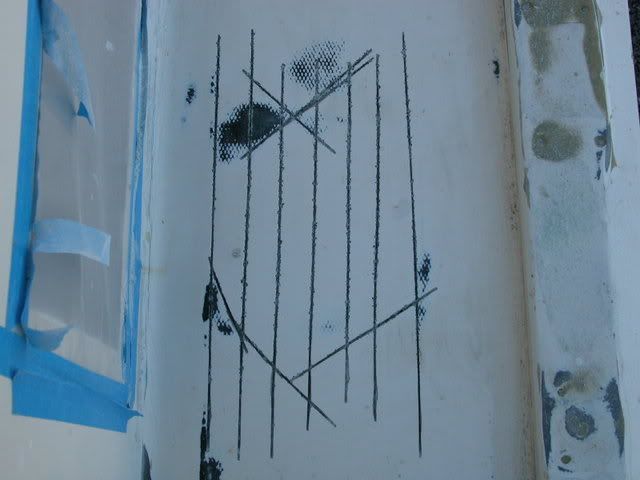

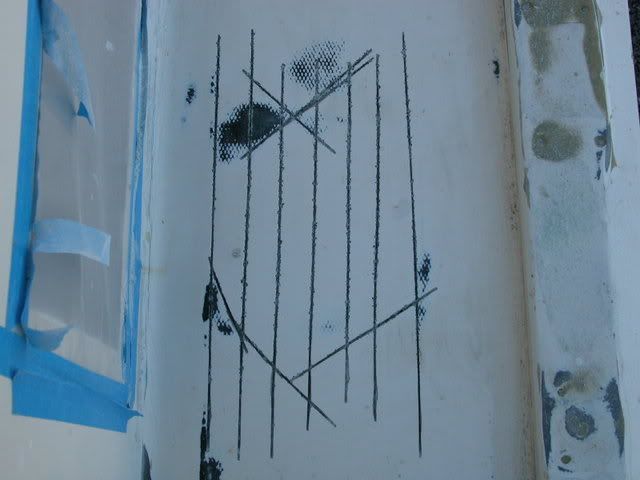

First I cut the area with a saw, making it easier to dig out the bad glass.

next we used a grinder with a 24grit disc to remove all the glass. Notice the beveled edge going outward.

Then we layered 1808 glass ( this is a biaxial glass with a matt backing ). I used West system epoxy to lay this up.

I should be able to post a couple more pics tomorrow on the next steps.

Hope this helps those who may be considering doing some of this type work.

We had 4 of these spots on the gunnels of Bosslady. As it turns out, these delaminating spots were over some heavy steel plates that I assume were used to pick up the top half of the boat and place it on the hull.

First I cut the area with a saw, making it easier to dig out the bad glass.

next we used a grinder with a 24grit disc to remove all the glass. Notice the beveled edge going outward.

Then we layered 1808 glass ( this is a biaxial glass with a matt backing ). I used West system epoxy to lay this up.

I should be able to post a couple more pics tomorrow on the next steps.

Hope this helps those who may be considering doing some of this type work.