Jasper

Well-known member

- Joined

- Dec 25, 2009

- Messages

- 334

- Status

- OWNER - I own a Hatteras Yacht

- Hatteras Model

- 53' CONVERTIBLE (1969 - 1980)

Another failure on Allison Gearbox.

The Port side gearbox (MH20) failed last year (forward gear) and was rebuilt.

At the time a new Hydreco oil pump was also installed.

The boat has been run around 20 hours since then.

In Queensland the fishing season has kicked off and I had the boat hauled, polished, propspeed etc.

Then, together with a mechanic friend, I serviced both engines, new filters, oil etc. But did not service the GB as it had only a few hours on it.

Last week, the boat was running perfectly. Engines have never run better, all gears fine. Until the next morning when the anchor was lifted. The Forward gear would NOT fully engage, except in idle.

I immediately checked the GB oil pressure. It read 40 psi in FWD.

Checked oil & it was dry.

Filled with 40w oil and pressure momentarily went to 155psi in gear, but still would not go past idle.

Then pressure was back to 40 psi. I shut down the engine & returned home on the Stbd motor.

The guys who rebuilt the gearbox came next day. They are very experienced with Allison’s and Detroit’s.

We checked the Hydreco, it was running perfect.

Cannot find any leaks.

Oil in the engine “seems” slightly higher than when I last checked.

Checked the filter in the 3 bolt flange fitting & found a small amount of clutch material but a lot of lint type material.

Gear selector was removed & tested, it is good.

All cables are working properly.

Lifted the gearbox off the engine & disassembled.

Clutch plate is still good, with very little wear.

Pressure plate has some burnt spots.

All bearings, gaskets & seals were good.

We shaved a thousandth off the back flywheel to the back of crank, just in case, even though it showed no damage.

The mechanics have spent the last week looking for a cause/problem.

In short, we cannot find anything wrong with the gearbox.

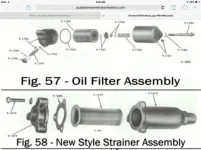

The ONLY major item damaged is the oil filter for the gearbox. When the filter casing was opened, the mechanic had to work very hard to remove the filter from the casing. The filter had been sucked deeply into the hose opening that leads to the control block. See the images. Unfortunately, this seems to be a symptom, not a cause for the loss of oil pressure. Seems the filter was starved of oil & was sucked into the hose. This was a new filter 20 hours ago!

Now the Gearbox will be re-installed, we will bypass the oil cooler momentarily to see whether there is a blockage there & check whether the gearbox works.

However, I believe that the it will work, which will then point to a blockage or problem in the oil cooler. So the oil cooler will then be removed & tested.

Is there a way of testing the oil cooler for blockages without removing it? I suggested compressed air, but apparently air will bypass an obstruction that oil will not.

Is there any cause for this problem that anyone can point to or advise on?

Everyone tells me that an Allison gearbox, once re-built, should be good for many years & thousands of hours!

This will be the 3rd rebuild I have had to do in 3 years! The 1st rebuild was apparently done incorrectly & the mechanics refunded the cost & recommended the present mechanics who have a good reputation.

They are doing the work under warranty, so you can imagine they are just as concerned as I am, to find the cause and make sure it does not happen again.

The Port side gearbox (MH20) failed last year (forward gear) and was rebuilt.

At the time a new Hydreco oil pump was also installed.

The boat has been run around 20 hours since then.

In Queensland the fishing season has kicked off and I had the boat hauled, polished, propspeed etc.

Then, together with a mechanic friend, I serviced both engines, new filters, oil etc. But did not service the GB as it had only a few hours on it.

Last week, the boat was running perfectly. Engines have never run better, all gears fine. Until the next morning when the anchor was lifted. The Forward gear would NOT fully engage, except in idle.

I immediately checked the GB oil pressure. It read 40 psi in FWD.

Checked oil & it was dry.

Filled with 40w oil and pressure momentarily went to 155psi in gear, but still would not go past idle.

Then pressure was back to 40 psi. I shut down the engine & returned home on the Stbd motor.

The guys who rebuilt the gearbox came next day. They are very experienced with Allison’s and Detroit’s.

We checked the Hydreco, it was running perfect.

Cannot find any leaks.

Oil in the engine “seems” slightly higher than when I last checked.

Checked the filter in the 3 bolt flange fitting & found a small amount of clutch material but a lot of lint type material.

Gear selector was removed & tested, it is good.

All cables are working properly.

Lifted the gearbox off the engine & disassembled.

Clutch plate is still good, with very little wear.

Pressure plate has some burnt spots.

All bearings, gaskets & seals were good.

We shaved a thousandth off the back flywheel to the back of crank, just in case, even though it showed no damage.

The mechanics have spent the last week looking for a cause/problem.

In short, we cannot find anything wrong with the gearbox.

The ONLY major item damaged is the oil filter for the gearbox. When the filter casing was opened, the mechanic had to work very hard to remove the filter from the casing. The filter had been sucked deeply into the hose opening that leads to the control block. See the images. Unfortunately, this seems to be a symptom, not a cause for the loss of oil pressure. Seems the filter was starved of oil & was sucked into the hose. This was a new filter 20 hours ago!

Now the Gearbox will be re-installed, we will bypass the oil cooler momentarily to see whether there is a blockage there & check whether the gearbox works.

However, I believe that the it will work, which will then point to a blockage or problem in the oil cooler. So the oil cooler will then be removed & tested.

Is there a way of testing the oil cooler for blockages without removing it? I suggested compressed air, but apparently air will bypass an obstruction that oil will not.

Is there any cause for this problem that anyone can point to or advise on?

Everyone tells me that an Allison gearbox, once re-built, should be good for many years & thousands of hours!

This will be the 3rd rebuild I have had to do in 3 years! The 1st rebuild was apparently done incorrectly & the mechanics refunded the cost & recommended the present mechanics who have a good reputation.

They are doing the work under warranty, so you can imagine they are just as concerned as I am, to find the cause and make sure it does not happen again.