MVCaprice

Well-known member

- Joined

- Aug 16, 2012

- Messages

- 663

- Status

- OWNER - I own a Hatteras Yacht

- Hatteras Model

- 61' MOTOR YACHT (1980 - 1985)

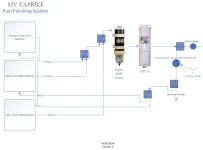

I have been piecing together a fuel polishing system. So far I have a Racor 1000 series, a Gulf Coast Filter F-1 and a 110v Oberdorfer pump and a 12 hour timer, lines and fittings. It should be a nice setup once its completed.

One area which I am still trying to plan for is around the main tank pickups. I already have 1/2" returns to each tank thanks to a previous owners efforts, but I need to add new pickups or tap the existing ones. In looking at the pickups that are already installed I was considering splitting the the existing pickup that is installed for the priming pump which seems to be a -6 or 3/8" JIC pickup on the main tank and splitting the primary generator pickup which his

One area which I am still trying to plan for is around the main tank pickups. I already have 1/2" returns to each tank thanks to a previous owners efforts, but I need to add new pickups or tap the existing ones. In looking at the pickups that are already installed I was considering splitting the the existing pickup that is installed for the priming pump which seems to be a -6 or 3/8" JIC pickup on the main tank and splitting the primary generator pickup which his

-6 or 3/8" JIC pickup as well. While I have the 3 way fittings to split the existing pickups, I am sort of concerned that it will be a large enough line for the polisher and other potential consequences of this setup.

If I wanted to drop in new pickups what fittings are commonly used for this? I assume a brass street elbow with a interference fit copper pickup tube?

If I wanted to drop in new pickups what fittings are commonly used for this? I assume a brass street elbow with a interference fit copper pickup tube?