Briankinley2004

Legendary Member

- Joined

- Jul 18, 2017

- Messages

- 1,520

- Status

- CAPTAIN

- Hatteras Model

- 55' CONV -Series I (1979 - 1988)

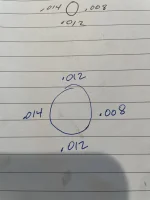

Replaced all three cutless bearings on my port side and splashed Friday. Decided to check the alignment this afternoon as I read it is best to do this in the water. Got the coupling unbolted and there was at least a .020" difference between the gap at the top of the coupling and the bottom. It seemed to be a uniform transition and the side measurements were close to the same. I dropped the front mounts about a 1/4 turn at a time until I got to the measurements in the picture below. This is facing the back of the engine looking forward. It seems the "right" side tightened up slightly more than the top and the "left" side is tightening up about like the bottom. Im trying to follow the geometry to figure out which mount I need to lower a bit more to get this right but I have hit a brain warp. Any of you folks with experience with this kind of work have any recommendations?