Buddy,

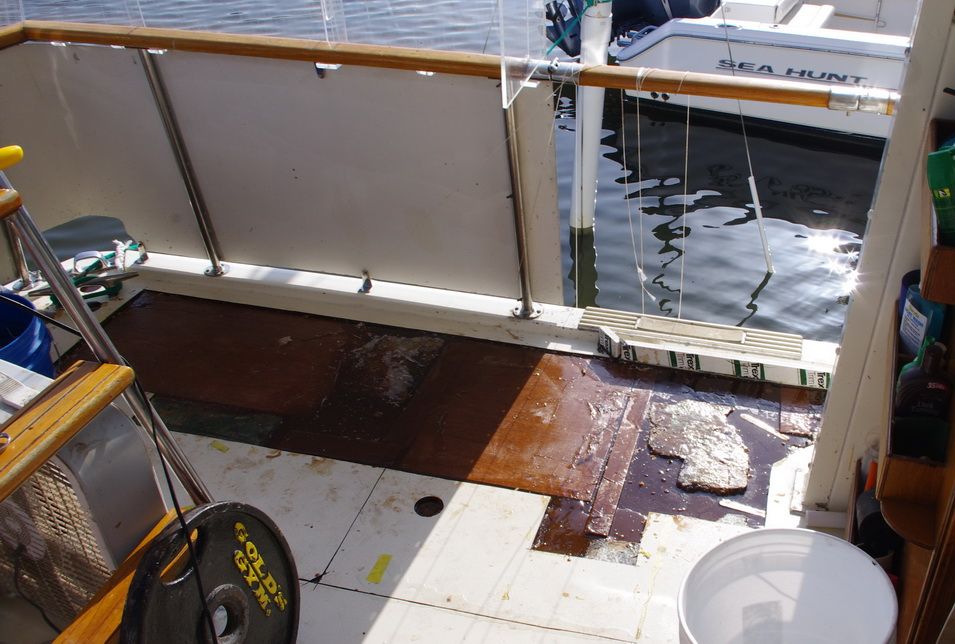

Interesting photos, good looking work. Your areas of bad core look very similar to what I found on Lilly Marie.

Sgharford,

I've seen how pw soaks up epoxy. I try to pre coat before gluing, and usually pour epoxy on to horizontal surfaces and spread the epoxy with a 4x6 plastic spreader. It uses a lot of epoxy but works. I use Raka brand, it works well and costs less than $60 / gallon.

Regards

Welcome to the Hatteras Owners Forum & Gallery. Sign Up or Login

+ Reply to Thread

Results 21 to 30 of 39

-

Re: Aft Deck Balsa Core Repair - How To / Not To

Regards,

Vincent Castigliola

Lilly Marie - 43 DC 1983

Pascagoula, Mississippi

Rather than history as a peaceful continuum interrupted by war, “For the first time in the nation's history men in authority are talking about an "emergency" without a foreseeable end" _ C. Wright Mills 1956

-

07-12-2012 08:50 AM #22

Re: Aft Deck Balsa Core Repair - How To / Not To

Sounds like you have a plan. I was lucky enough to have friend with commercial Port Supply account at local West Marine, the discounts are way better then even Defender with that card. We bought thickeners (colloidal silica and flocked cotton) in 5 gallon buckets from fiberglass supply shop. Some stand out advice I can offer for fairing the final 3rd layer of plywood for lining up seam of upper skin, a heavy duty 9" right angle sander (not DA, but circular, like a grinder) with 60 grit paper sure seemed like the right tool for taking off that much material. It also worked great for cleaning up the left over balsa on lower and upper skin. We also used chopped matt when filling upper skin seam, apparently this is important, otherwise good chance it will crack over time. We used DA and flat orbital sanders for the final fairing on seams. With the final epoxy coat on seams we used West System 407 low density filler which worked very well.

-

Re: Aft Deck Balsa Core Repair - How To / Not To

Sgharford,

Your pictures and comments have been very helpful.

I have a Makita sander/polisher which should do the job of beveling the seams and then grinding off the excess. I have a roll of 1" fg cloth tape for the straight seams and cloth to place over the plugs. Chopped mat sounds interesting as a high strength filler.

One question. What is a "DA"? Often times I feel like one, but I don't think that is what you meant in this case.

Regards,Regards,

Vincent Castigliola

Lilly Marie - 43 DC 1983

Pascagoula, Mississippi

Rather than history as a peaceful continuum interrupted by war, “For the first time in the nation's history men in authority are talking about an "emergency" without a foreseeable end" _ C. Wright Mills 1956

-

07-12-2012 10:58 AM #24

Re: Aft Deck Balsa Core Repair - How To / Not To

Glad I can offer some help. DA sander = Dual Action. It spins and orbits. It's my go to sander for nearly everything, they are primarily what body shops used to fair down body fillers and the like (at least they were 20 years ago). You can really take allot or a little down with them and easy to maneuver. I highly recommend adding one to the tool chest, you can get them online and even at home depot.

-

Re: Aft Deck Balsa Core Repair - How To / Not To

After cleaning the antifreeze and vacuuming the water we had a serious thunderstorm which flooded things. After another vacuuming, I built a "tent" frame out of 1" pvc and enclosed the area with clear plastic sheeting. I then set up a dehumidifier inside and let it run until wouldn't take out any more water. I then set up a small window unit air conditioner to keep things dry and make the space cool enough to work. I wish I had taken some pictures, as it worked well.

The weather forecast showed significant chance of thunderstorms over the next several days but last night looked pretty good so I started filling the deck core voids with plywood, epoxy, wood flour and chopped fg strand working well into the night.

I am pleased to report that the area is now sealed with epoxy. It is not pretty, but I won't go into depression if it rains now.

I hope to be able to reattach the upper skin this weekend. My plan is to mark the vertical contour with a batten and small wood shims stuck to the deck with double side tape add very thick epoxy spread up to the points set by the shims and then coat the underside of the fiberglass deck section with more filled epoxy then place the fiberglass skin on top of the shims.

Once the epoxy has set up I will go over the seams with a grinder sander then epoxy fiberglass tape along the seams.

To get the water and then the epoxy to flow aft and to the port, I placed a couple of 150 qt ice chests on the port side of the swim platform and filled them with water. With the epoxy in place, I have drained the ice chests,

and will move the up to the stb bow to make the side and aft cambered deck closer to level. Hope it is presentable by rondezvous time.

Any suggestions on a low gloss 2-part brushable polyurethane that will match the older Hatteras off-white?Last edited by Vincentc; 07-13-2012 at 02:24 PM.

Regards,

Vincent Castigliola

Lilly Marie - 43 DC 1983

Pascagoula, Mississippi

Rather than history as a peaceful continuum interrupted by war, “For the first time in the nation's history men in authority are talking about an "emergency" without a foreseeable end" _ C. Wright Mills 1956

-

Re: Aft Deck Balsa Core Repair - How To / Not To

It took starting work at 3:30 this morning but I got things closed up before the thunderstorms came through.

The Makita grinder/sander/polisher with a 50 grit disk, smoothed things up and cut through freshly cured epoxy easily.

I cut an assortment of wood spacers ranging from tongue depressors, 1.5 mm to 9mm plywood and then used a batten to see how much spacer I needed. I then used an 18ga stapler to tack down the spacers.

I then poured epoxy thickened with wood flour and chopped strand into the void space and spread it to the tops of the spacers. I coated the underside of the top skin and then put the top skin pieces back in place and secured them with an assortment of weights.

Once I started mixing and pouring epoxy I did not handle the camera so pictures are limited. I use nitrile disposable gloves and buy them by the box from a local safety supply store. They are thin and easy to work with, but tear easily.

continuedRegards,

Vincent Castigliola

Lilly Marie - 43 DC 1983

Pascagoula, Mississippi

Rather than history as a peaceful continuum interrupted by war, “For the first time in the nation's history men in authority are talking about an "emergency" without a foreseeable end" _ C. Wright Mills 1956

-

Re: Aft Deck Balsa Core Repair - How To / Not To

Not only did I beat the thunderstorms but I got everything poured and in place before the epoxy kicked off. I did have a problem with the chopped strand thickened epoxy getting on top of the spacers and keeping the deck skin from settling down as far as needed.

Once the epoxy had hardened, but was still green, I started removing the weights and trimming the excess with a multitool and a wood cutting blade.

I plan on working on the seams and high spots with the Makita sander tomorrow.

I believe that things will work out fine, but I could have done a better job if I had not been pressured by thunderstorms and the prospect of having to dry things out over and over. I should have spent more time setting up weather protection. The aft deck enclosure does not prevent all water from getting and taping up visqueen and sheet vinyl with masking tape is not good enough. Closing things up and using a dehumidifier is important. I am not going to dwell on that because I need to get thing a little better looking for the weekend.

Regards,Regards,

Vincent Castigliola

Lilly Marie - 43 DC 1983

Pascagoula, Mississippi

Rather than history as a peaceful continuum interrupted by war, “For the first time in the nation's history men in authority are talking about an "emergency" without a foreseeable end" _ C. Wright Mills 1956

-

Re: Aft Deck Balsa Core Repair - How To / Not To

The excess epoxy sands off well with the grinder. I went over the seams with the grinder removing the gel coat and creating a depression along the seams. I epoxied one inch wide ten oz fg tape along the seam followed by 3" tape.

There are a couple of low spots where the panels did not quite match up and I filled the depressions with filled epoxy.

Grinding fiberglass is not one of my favorite things and I am itching to get this project completed. I believe I will remove the wood stud supports tomorrow and see how things lay.

RegardsRegards,

Vincent Castigliola

Lilly Marie - 43 DC 1983

Pascagoula, Mississippi

Rather than history as a peaceful continuum interrupted by war, “For the first time in the nation's history men in authority are talking about an "emergency" without a foreseeable end" _ C. Wright Mills 1956

-

07-17-2012 11:31 PM #29

Senior Member

Senior Member

- Join Date

- Jan 2006

- Posts

- 822

Re: Aft Deck Balsa Core Repair - How To / Not To

What are you using for a fairing compound? The west brand flows out well and sands a lot better than cabosil

-

Re: Aft Deck Balsa Core Repair - How To / Not To

I am using wood flour and chopped strand as a base filler, the top coat before the fg tape was just epoxy and wood flour which the 50 grit grinder disk cuts through easily. I have some phenolic microballons which I will use for faring. The West Microlite filler is really smooth, but I don't have any on hand. Both will sand easily. I agree, Cabosil doesn't sand very well.

I am pleased to report that I removed the stud walls last night and checking this am, it does not appear that the deck sagged back. I hope to put some white epoxy primer over the filled areas and get the deck a little more presentable for the rendezvous.

Regards,Regards,

Vincent Castigliola

Lilly Marie - 43 DC 1983

Pascagoula, Mississippi

Rather than history as a peaceful continuum interrupted by war, “For the first time in the nation's history men in authority are talking about an "emergency" without a foreseeable end" _ C. Wright Mills 1956

Reply With Quote

Reply With Quote